Industry information

Company News

- Fluorocarbon aluminum veneer: creating an "invisible garment" for fashionable architecture!

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

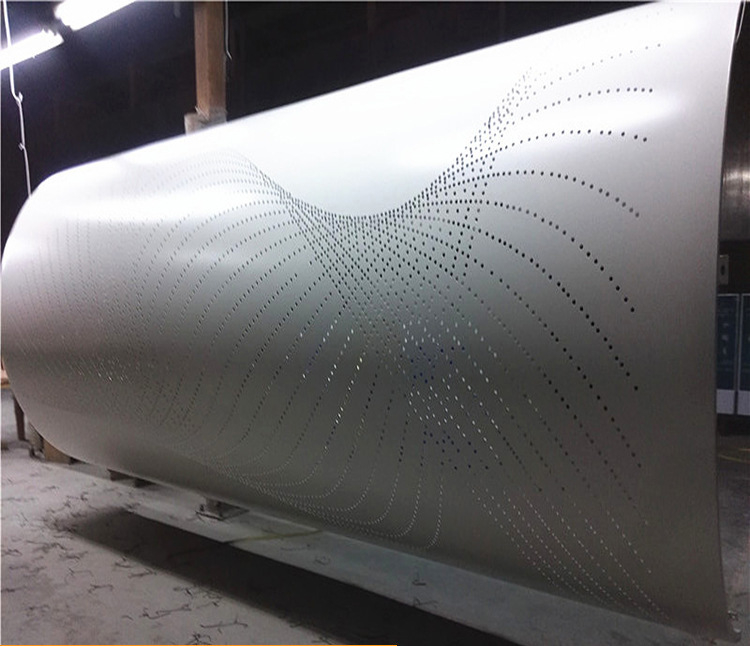

- The unique charm of punched aluminum veneer: not just decoration, but also art

- Fluorocarbon aluminum veneer: the 'invisible guardian' of modern architecture

- Punched aluminum veneer: a fashionable choice for modern architecture

Industry dynamics

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- Key points for choosing carved aluminum veneer

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

- Analysis of installation difficulties of aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

Frequently asked questions

- What is the fire resistance of aluminum veneer?

- What are the common methods for surface treatment of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

How to control the cost of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 13, 2025 11:38:00

- Click:0

As a common building material, cost control of aluminum veneer is also one of the key concerns for enterprises. Below, we will provide a detailed introduction to the cost control methods and techniques for aluminum veneer.

1. Procurement cost control

Procurement cost is one of the main factors affecting the cost of aluminum veneer, so it is necessary to strengthen procurement management and reduce procurement costs. Specific measures include:

(1) Reasonably select suppliers, conduct price comparisons and negotiations, and strive to obtain more favorable prices;

(2) Optimize the procurement process, reduce procurement steps, and improve procurement efficiency;

(3) Adopting centralized procurement methods to achieve economies of scale and reduce procurement costs.

1. Production cost control

Production cost is an important component of aluminum veneer cost, therefore it is necessary to strengthen production management and reduce production costs. Specific measures include:

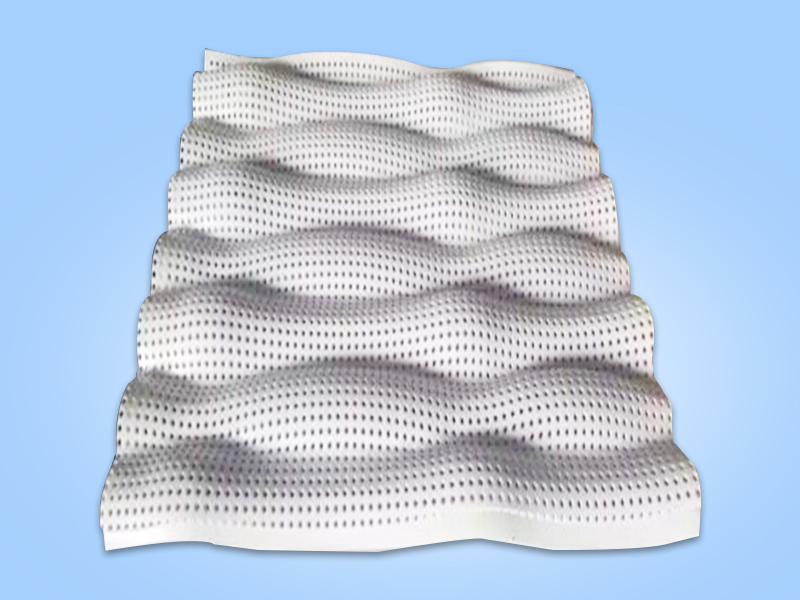

(1) Optimize production processes and equipment to improve production efficiency and quality;

(2) Strengthen raw material procurement and management to reduce raw material costs;

(3) Implement lean production, reduce waste and loss, and lower production costs.

1. Sales cost control

The cost of sales is one of the important factors affecting the profit of aluminum veneer enterprises, so it is necessary to strengthen sales management and reduce sales costs. Specific measures include:

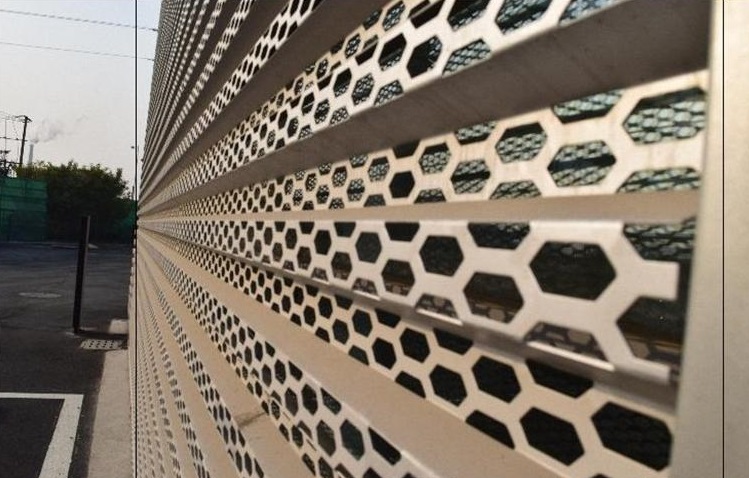

(1) Optimize product structure and service model, enhance product added value and market competitiveness;

(2) Strengthen channel management and expansion, expand market share;

(3) Reduce marketing and promotional costs, and improve sales efficiency.

1. Management cost control

Management costs are one of the important factors affecting the comprehensive benefits of aluminum veneer enterprises, therefore it is necessary to strengthen enterprise management and reduce management costs. Specific measures include:

(1) Optimize organizational structure and management processes to improve management efficiency;

(2) Strengthen talent introduction and training, improve employee quality and work efficiency;

(3) Promote information management, improve management level and decision-making efficiency.

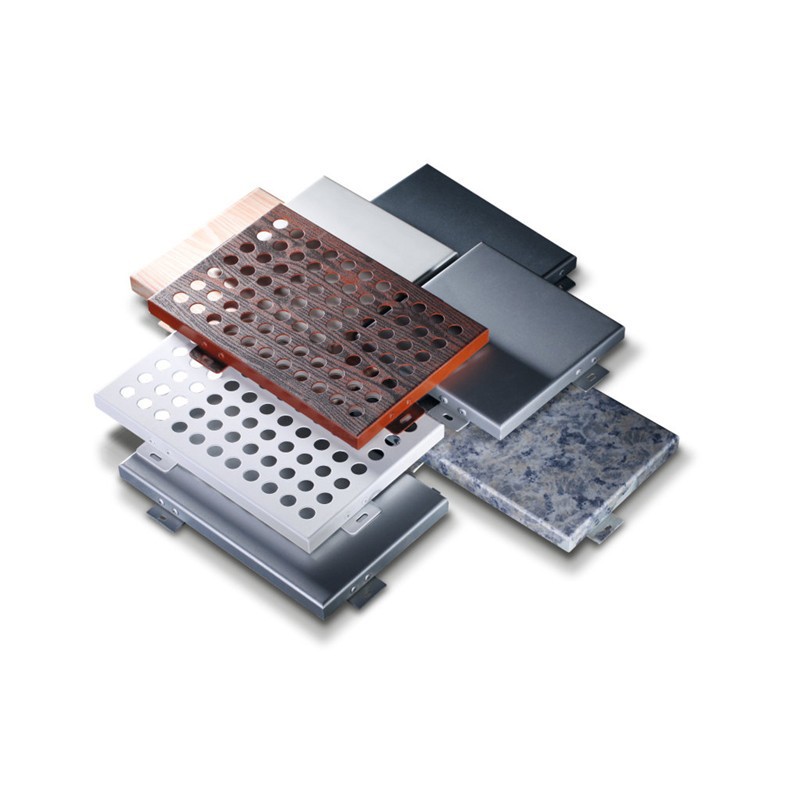

The cost control of aluminum veneer needs to start from multiple aspects such as procurement, production, sales, and management, and adopt a series of effective measures and management strategies to ensure that the quality and performance of aluminum veneer meet the requirements, achieve effective cost control, and maximize economic benefits. We also need to strengthen technological innovation and research and development efforts, constantly innovate and contribute to the sustainable development of the construction industry.

Customer service QQ

Customer service QQ