Frequently asked questions

Company News

- Aluminum veneer specifications and customized services to meet customers' personalized needs

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer curtain wall, the "fashionable coat" of modern architecture

- Aluminum veneer curtain wall: the green guardian of modern architecture

Industry dynamics

- Surface treatment technology and development trend of aluminum veneer

- Aluminum veneer: a fashionable choice in modern architecture

- Punched aluminum veneer: the new darling of creative space!

- Fluorocarbon aluminum veneer: the new darling of modern architecture?

- Punched aluminum veneer: a fashionable "lightweight" choice in modern architecture

Frequently asked questions

- What is the insulation performance of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- What is the sound insulation performance of aluminum veneer?

- What is the fire resistance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

What are the surface treatment methods for aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 28, 2025 00:56:14

- Click:0

What are the surface treatment methods for aluminum veneer?

Aluminum veneer is a common building decoration material widely used in fields such as building facades and interior decoration. In order to improve its aesthetics, durability, and functionality, aluminum veneer needs to undergo surface treatment. This article will elaborate on the surface treatment methods of aluminum veneer from the following four aspects.

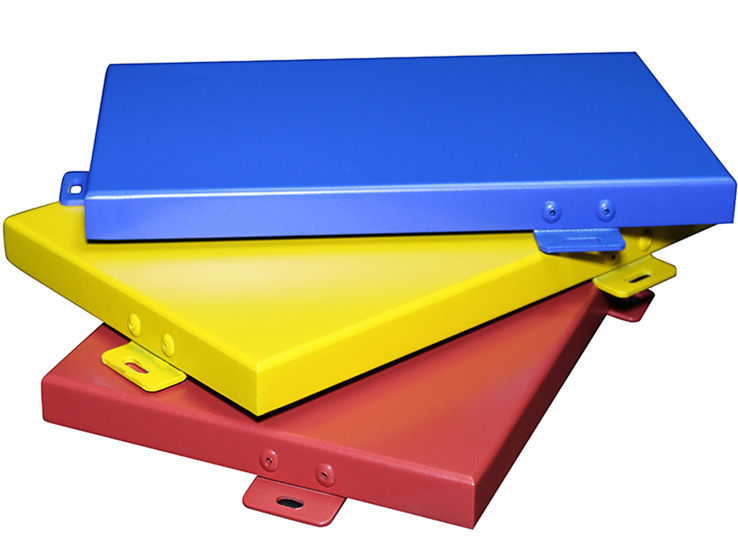

1、 Spray surface treatment

1. Paint spraying: Spray paint evenly onto the surface of aluminum veneer using a spray gun, and then dry and cure it through high-temperature baking. This method can achieve rich color choices and diverse effects, such as matte, metallic texture, etc.

2. Powder spraying: Powder coating is electrostatically adsorbed onto the surface of aluminum veneer through spraying equipment, and then baked at high temperature to melt, level, and solidify it. Powder coating has high weather resistance and corrosion resistance, and can also achieve a variety of color and texture choices.

3. Oxidation spraying: A layer of oxide film is formed on the surface of aluminum veneer, which can be achieved through anodizing or electrophoretic coating techniques. Oxidation spraying can enhance the weather resistance and corrosion resistance of aluminum veneer, while also achieving a metallic texture effect.

2、 Mechanical surface treatment

1. Polishing: By mechanical grinding, the unevenness and oxide layer on the surface of aluminum veneer are removed, making its surface smoother and more delicate. The polished aluminum veneer has better reflection performance and tactile sensation, making it suitable for applications that require high brightness.

2. Sanding: Using abrasives to impact aluminum veneer, forming a uniform sandy texture. Sanding surface treatment can enhance the anti slip performance of aluminum veneer and also increase the decorative effect.

3. Carving: Carving patterns or text onto the surface of aluminum veneer using mechanical or laser carving techniques. Carving surface treatment can enhance the artistic sense and personalized characteristics of aluminum veneer, and is commonly used in interior decoration.

3、 Chemical surface treatment

1. Fluorocarbon spraying: Using fluorocarbon resin coating to treat the surface of aluminum veneer, forming a protective layer against dirt and corrosion. Fluorocarbon spraying can achieve long-term aesthetic and easy to clean effects, and is widely used in outdoor environments.

2. Anodizing: By electrolysis, a layer of oxide film is formed on the surface of aluminum veneer to increase its hardness and corrosion resistance. Anodizing can achieve multiple color choices and has certain insulation properties, commonly used in indoor decoration and electronic fields.

3. Acid washing treatment: Use acidic solution to treat the surface of aluminum veneer, remove the oxide layer and impurities, and make it cleaner. Acid washing treatment can improve coating adhesion and extend the service life of aluminum veneer.

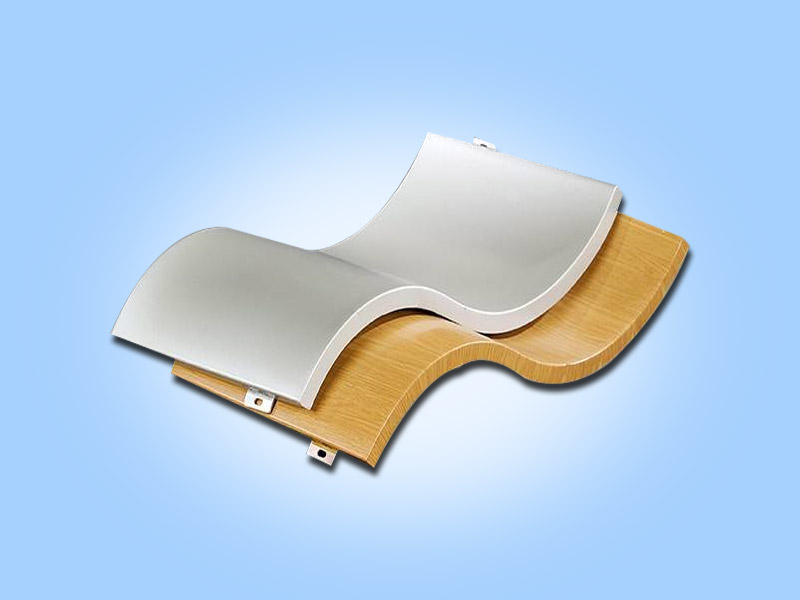

4、 Special surface treatment

1. Wood grain heat transfer printing: Using heat transfer printing technology to transfer wood grain patterns onto the surface of aluminum veneer, achieving a wood grain like effect. Wood grain heat transfer printing treatment can simultaneously balance the aesthetic appearance and durability of aluminum veneer.

2. Stone pattern coating: Through a special coating process, a stone like effect is formed on the surface of aluminum veneer. Stone pattern coating can give aluminum veneer the texture and aesthetics of stone, suitable for fields such as building facades.

3. Nano spraying: Using nanotechnology to form nanoparticles in coatings, allowing them to adhere more evenly to the surface of aluminum veneer. Nano spraying can improve the stain resistance and weather resistance of aluminum veneer, while also having a certain self-cleaning effect.

Summary:

There are various surface treatment methods for aluminum veneer, each with its unique advantages and applicable scenarios. Spray surface treatment can achieve rich color choices and effects, mechanical surface treatment focuses on smoothness and decorative effects, chemical surface treatment can increase protective layer and corrosion resistance, while special surface treatment emphasizes simulation effects and personalized characteristics. Choosing the appropriate surface treatment method based on specific needs and application scenarios can improve the overall quality and service life of aluminum veneer.

- Previous Page: None

- Next page:What is the sound insulation performance of aluminum veneer?

Customer service QQ

Customer service QQ