Industry information

Company News

- Aluminum veneer curtain wall: a fashionable outerwear for urban architecture

- Exploring the unique charm of fluorocarbon aluminum veneer

- Aluminum veneer customization, creating a new trend of personalized space

- Personalized aluminum veneer customization, creating a unique storefront style

- Aluminum veneer curtain wall: the new darling of future architectural aesthetics?

Industry dynamics

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization injects new design concepts into buildings

- Aluminum veneer: the "fashionable coat" of modern architecture

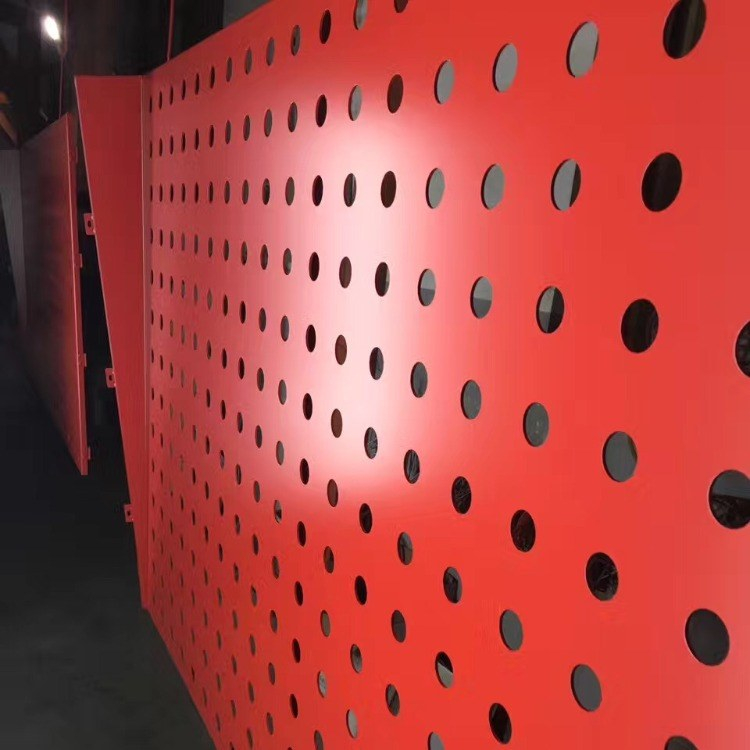

- Aluminum plate punching, infinite creativity, breathtaking beauty!

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

Frequently asked questions

- What is the installation method of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- What is the fire resistance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- What is the insulation performance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

What are the methods for surface treatment of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-12 20:24:26

- Click:0

Aluminum veneer, as a new type of building material, has diverse surface treatment methods. Let's learn about the surface treatment methods of aluminum veneer together.

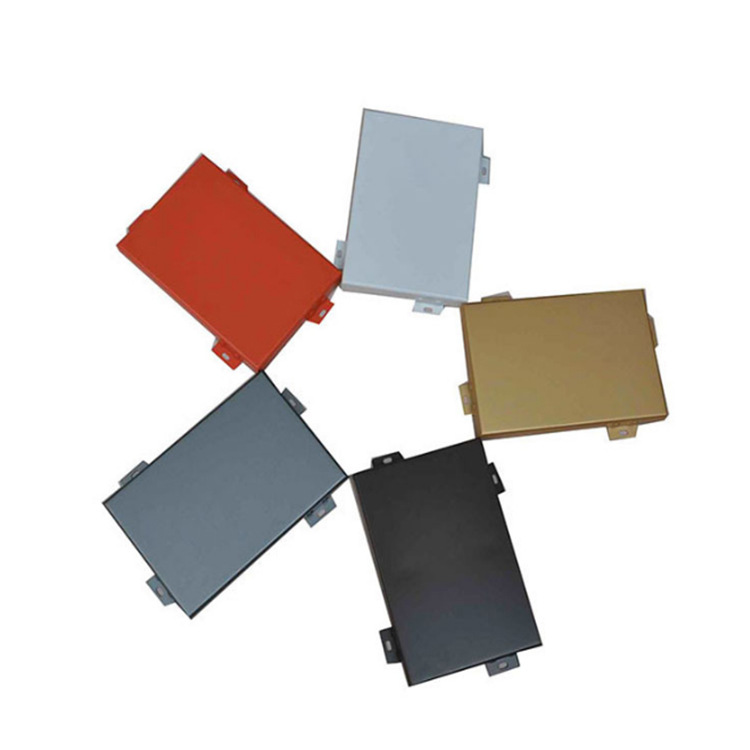

The surface treatment methods for aluminum veneer mainly include spraying, rolling, and anodizing. Spraying is a commonly used surface treatment method that can give aluminum veneers different color and texture effects. During the spraying process, different types of coatings such as polyurethane, acrylic, etc. are usually used to achieve different decorative effects and anti-corrosion properties.

Roll pressing is a relatively simple surface treatment method that can form a flat metal film on the surface of aluminum veneer. This processing method is usually applicable to some simple areas of building exterior walls, such as commercial and residential buildings.

In addition, anodizing is an advanced surface treatment method that can enhance the corrosion resistance and wear resistance of aluminum veneer. In this processing method, the aluminum veneer will be placed in an electrolyte solution for oxidation treatment, thereby forming a layer of aluminum oxide film. This film has good corrosion resistance and wear resistance, which can extend the service life of aluminum veneer.

There are also some other surface treatment methods, such as fluorocarbon spraying, heat transfer printing, etc. These processing methods are usually applicable to some high-end construction fields, such as airports, subway stations, etc. These places have high requirements for the appearance and decoration of buildings, so more advanced surface treatment methods are needed to meet the needs.

It should be noted that different surface treatment methods will have different effects on the performance of aluminum veneer. For example, when choosing a surface treatment method, factors such as decorative effect, anti-corrosion performance, and wear resistance need to be considered. Only by fully understanding these factors can one choose aluminum veneer products that are suitable for their own needs and fully leverage their advantages. We still need to constantly explore and innovate, develop more environmentally friendly, energy-saving, and sustainable building materials and technologies, and promote the sustainable development of the construction industry.

- previous page:What are the maintenance steps for aluminum veneer?

- Next page:How to control the cost of aluminum veneer?

Customer service QQ

Customer service QQ