Industry information

Company News

- Aluminum Veneer: Unveiling the Fashion 'Cloak' in the Architecture Industry

- Aluminum veneer curtain wall, creating a fashionable "coat" for modern architecture

- Aluminum veneer curtain wall: the beauty of architecture, the choice of details

- The charm of perforated aluminum veneer creates a personalized space!

- Surface treatment and color selection of aluminum veneer

Industry dynamics

- Aluminum veneer: the fashion "new favorite" in the construction industry

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer curtain wall, the new darling of architectural art!

- Aluminum veneer: the "fashionable coat" of modern architecture

- Unlimited creativity, perforated aluminum veneer: a new trend in aluminum materials

Frequently asked questions

- What is the insulation performance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- What is the installation method of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

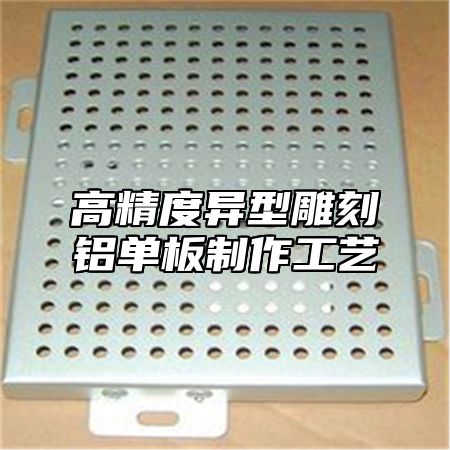

Manufacturing process of high-precision special-shaped carved aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 26, 2025 21:27:48

- Click:0

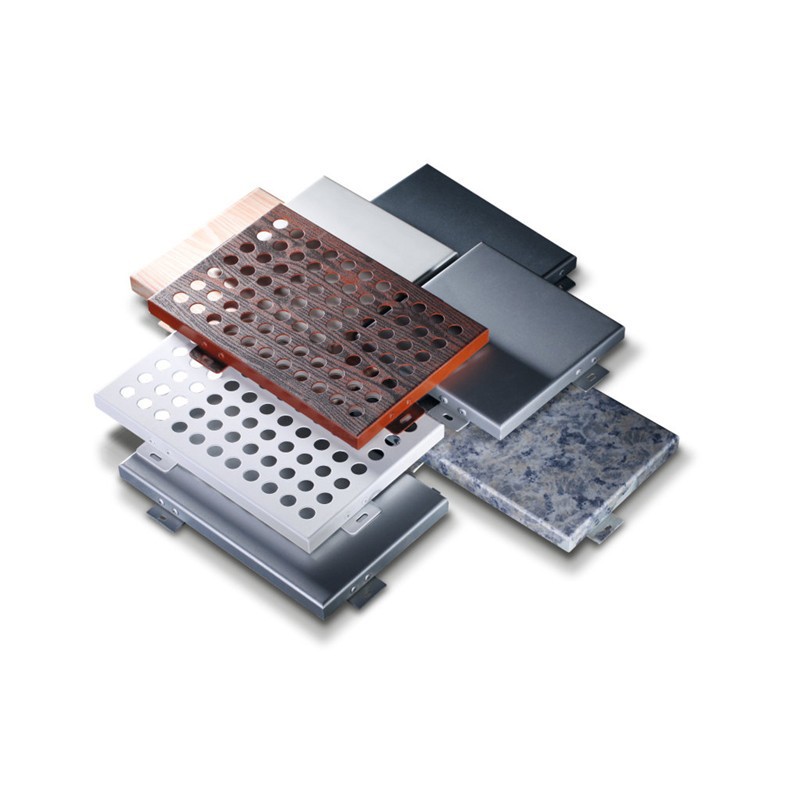

Irregular carved aluminum veneer is a high-end decorative material, and its production process requires high precision and high technical level. The following is some information about the production process of high-precision special-shaped carved aluminum veneer.

1、 Raw material preparation

1. Aluminum alloy sheet: The main raw material for high-precision special-shaped carved aluminum veneer is aluminum alloy sheet, and high-quality aluminum alloy materials need to be selected to ensure product quality and performance.

2. Cutting tools: High precision special-shaped carved aluminum veneer requires the use of professional cutting tools for carving processing, and the quality and accuracy of the cutting tools directly affect the quality and performance of the product.

3. Auxiliary equipment: The production of high-precision special-shaped carved aluminum veneer also requires the use of some auxiliary equipment, such as CNC machine tools, laser cutting machines, etc., to improve production efficiency and quality.

2、 Design and production

1. CAD design: Firstly, CAD design is required to develop product design and production plans based on customer requirements and needs.

2. CNC machining: The designed product is processed by CNC machine tools to ensure the accuracy and size of the product.

3. Laser cutting: The processed aluminum veneer is laser cut to form the desired shape and size.

4. Surface treatment: Anodize the cut aluminum veneer to increase its corrosion resistance and aesthetics.

5. Carving processing: Fine carving processing is carried out on the surface treated aluminum veneer to achieve the desired patterns and designs.

3、 Quality inspection

1. Dimensional inspection: Conduct a dimensional inspection on the processed aluminum veneer to ensure that the product's dimensions meet the requirements.

2. Appearance inspection: Conduct a visual inspection of the processed aluminum veneer to check for defects and deficiencies.

3. Strength testing: Conduct strength testing on the processed aluminum veneer to ensure that it has sufficient strength and stability.

4、 Packaging and transportation

1. Packaging: Packaging the aluminum veneer that has completed quality inspection to protect the product from damage.

2. Transportation: Transport the packaged aluminum veneer to ensure its safe arrival at the destination.

The production process of high-precision special-shaped carved aluminum veneer requires multiple steps including raw material preparation, design and production, quality inspection, and packaging and transportation. Only through strict manufacturing processes and management procedures can we ensure the quality and performance of our products, and meet the needs and requirements of our customers.

Customer service QQ

Customer service QQ