Industry information

Company News

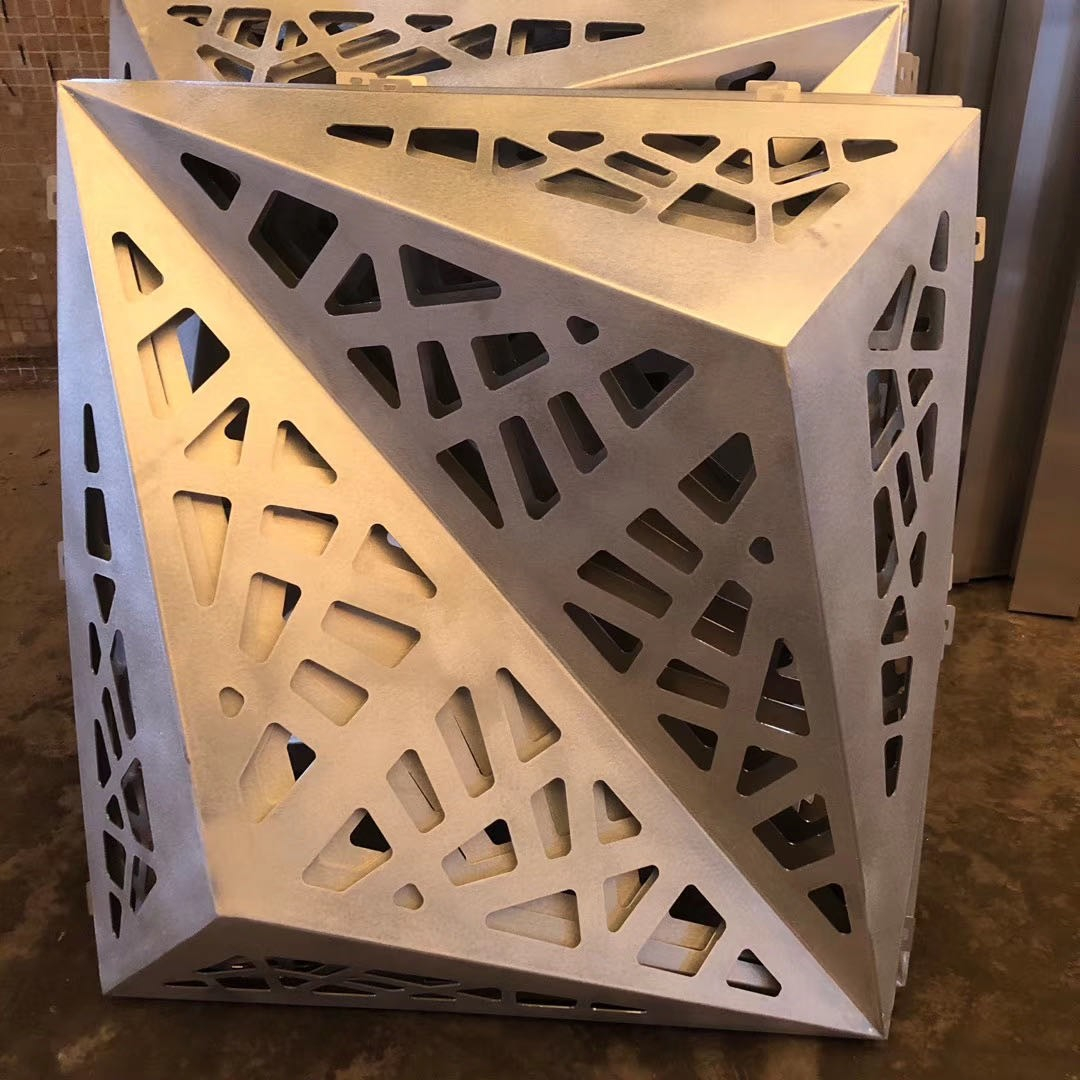

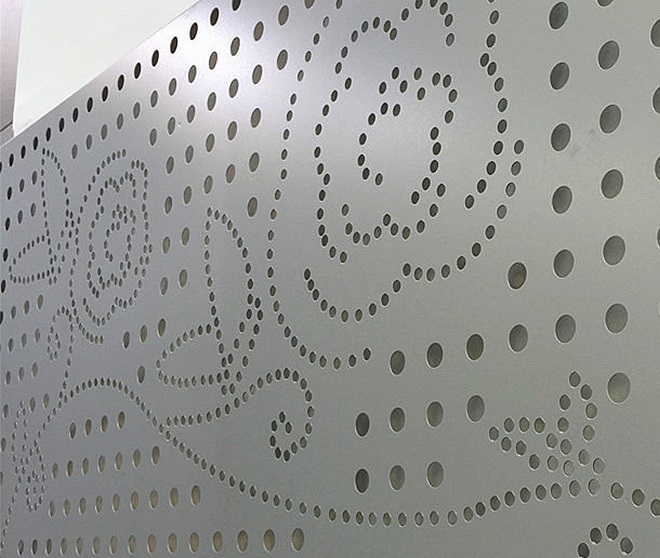

- New Talent in Aluminum Plate: The Unique Charm of Punched Aluminum Veneer

- Aluminum veneer punching, a space magician with infinite creativity

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer: the new favorite of the construction industry and the secret weapon of the light luxury trend!

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer curtain wall, the "fashionable coat" of modern architecture

- Fluorocarbon aluminum veneer: the new favorite of aluminum materials, a new chapter in the beauty of architecture

- Exploring perforated aluminum veneer: the fashionable choice in modern architecture!

- How to control the cost of aluminum veneer?

Frequently asked questions

- What is the installation method of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- What are the common methods for surface treatment of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

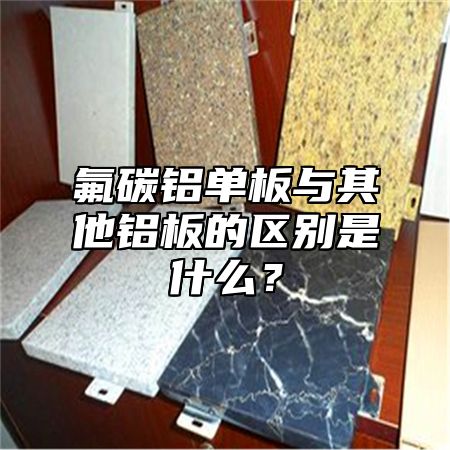

What is the difference between fluorocarbon aluminum veneer and other aluminum sheets?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 27, 2025 21:06:16

- Click:0

Fluorocarbon aluminum veneer is a very popular building material that has many advantages compared to other aluminum panels. Below, we will provide a detailed introduction to the differences between fluorocarbon aluminum veneer and other aluminum sheets.

1、 Different surface treatments

The surface of fluorocarbon aluminum veneer is treated with fluorocarbon coating, which has good weather resistance and corrosion resistance, and can resist the effects of ultraviolet rays, acid rain, oxidation and other factors. However, other aluminum plates usually use surface treatment methods such as anodizing and spraying, which have relatively poor durability and corrosion resistance.

2、 Different strength and stiffness

The main skeleton material of fluorocarbon aluminum veneer is aluminum alloy, usually processed and produced using series of aluminum alloy sheets such as 1100, 3003, 5052, etc. These aluminum alloy sheets have high strength and rigidity, and can support the overall structure of fluorocarbon aluminum veneer. However, the strength and stiffness of other aluminum plates are relatively low and cannot withstand large loads.

3、 Different weight and density

Fluorocarbon aluminum veneer has a relatively light weight and low density, which makes it more convenient and efficient to construct. It can also reduce the overall weight of buildings and improve their seismic performance. However, the weight and density of other aluminum plates are relatively high, which has a certain impact on the stability performance of construction and buildings.

4、 Different processability and installation methods

Fluorocarbon aluminum veneer has good plasticity and processability, and can be processed and customized in various shapes and sizes. The installation of fluorocarbon aluminum veneer is relatively simple, only requiring the use of ordinary screws and rivets to complete the installation. However, the processing and installation of other aluminum plates are relatively difficult and require complex fixing methods.

5、 Different appearance and decorative effects

After being treated with fluorocarbon coating, the surface of fluorocarbon aluminum veneer has a beautiful appearance and glossiness, which can meet the needs of various building decorations. However, the appearance and decorative effect of other aluminum plates are relatively poor, and cannot meet the aesthetic requirements of commercial and residential building decoration fields.

The differences between fluorocarbon aluminum veneer and other aluminum sheets mainly lie in surface treatment, strength and stiffness, weight and density, processability and installation methods, as well as appearance and decorative effects. When selecting materials, it is necessary to comprehensively consider the relationship between these factors based on actual needs, and choose product and service suppliers that meet actual needs.

Customer service QQ

Customer service QQ