Industry information

Company News

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer curtain wall, a new interpretation of the beauty of architecture

- Aluminum veneer curtain wall: the beauty of architecture, the charm of details

- Aluminum veneer curtain wall: a lightweight choice for architectural art

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Unveiling the Charm and Secrets of Punched Aluminum Veneer

- Twisted ceiling aluminum veneer creates a comfortable and beautiful office environment

- Exquisite craftsmanship creates brilliance - Carving roller coated aluminum veneer for architectural decoration

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

Frequently asked questions

- What is the sound insulation performance of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- What is the fire resistance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Selection of fireproof perforated aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 26, 2025 16:26:02

- Click:0

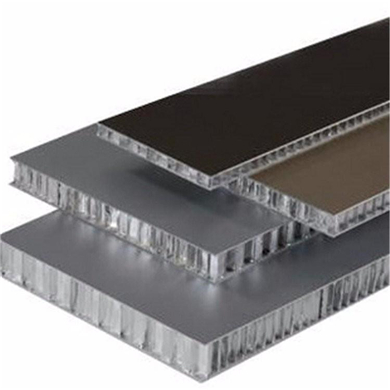

Fireproof perforated aluminum veneer is a building material with fire-resistant properties, widely used in fields such as building decoration, billboards, and home decoration. It is made using punching technology and has good sound insulation, heat insulation, fire resistance and other properties. This article will provide a detailed introduction on how to choose fire-resistant perforated aluminum veneer from multiple aspects.

1、 Material characteristics

The main characteristic of fireproof perforated aluminum veneer is that its material has good fireproof performance. It is usually made of aluminum alloy sheet through punching process, and the surface is specially treated to give it a certain degree of fire resistance. Fireproof perforated aluminum veneer also has advantages such as sound insulation and thermal insulation, which can effectively improve the safety and comfort of buildings.

2、 Select key points

1. Fire rating: When choosing fire-resistant perforated aluminum veneer, the first thing to consider is its fire rating. According to national standards, fire protection levels are divided into three levels: A, B, and C. Among them, A grade fireproof materials have the highest fire resistance and are suitable for high-rise buildings and public places; The fire resistance performance of B-grade fireproof materials is second, suitable for general buildings; C-grade fire-resistant materials have low fire resistance and are suitable for some low rise buildings and private residences.

2. Thickness: The thickness of fireproof perforated aluminum veneer is also one of the factors to consider when choosing. Generally speaking, the thicker the thickness, the better its fire resistance performance. However, excessively thick aluminum plates can increase the weight and cost of buildings, so it is necessary to choose according to the actual situation.

3. Surface treatment: The surface treatment of fireproof perforated aluminum veneer is also one of the factors to consider when choosing. The common surface treatment methods on the market currently include anodizing, spraying, and rolling. Anodizing treatment can form a dense oxide film on the surface of aluminum plates, improving their corrosion resistance and wear resistance; Spraying treatment can increase the aesthetics and corrosion resistance of aluminum plates; Roll pressing treatment can make the surface of the aluminum plate smoother and more even.

3、 Case sharing

The following is a successful case of fireproof perforated aluminum veneer: A high-rise commercial complex used fireproof perforated aluminum veneer as a curtain wall decoration material, and through scientific design and construction management, successfully completed its installation work. This commercial complex not only enhances the overall aesthetics and practicality of the building, but also conforms to the environmental protection concept of modern society. This application solution has set an example for the development of the industry.

Fireproof perforated aluminum veneer, as a new type of building material, has good fire resistance and advantages such as sound insulation and thermal insulation. When choosing, it is necessary to consider factors such as fire rating, thickness, and surface treatment to ensure that it can meet the needs of different fields. Only through scientific design and strict construction management can its advantages be fully utilized to improve the safety and comfort of buildings.

Customer service QQ

Customer service QQ