Industry information

Company News

- Aluminum veneer curtain wall: the beauty of architecture, the charm of details

- Uncover the charm and secrets of fluorocarbon aluminum veneer!

- Curtain Wall Aluminum Veneer: A Journey of Aesthetic Innovation in Modern Architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: creating an "invisible garment" for fashionable architecture!

Industry dynamics

- Personalized customization, aluminum veneer interprets unique aesthetics

- Market competitiveness of aluminum veneer manufacturers

- Analysis of Material and Characteristics of Hyperbolic 1.5mm Aluminum Veneer

- Can the insulation function of aluminum veneer be applied to high-rise buildings?

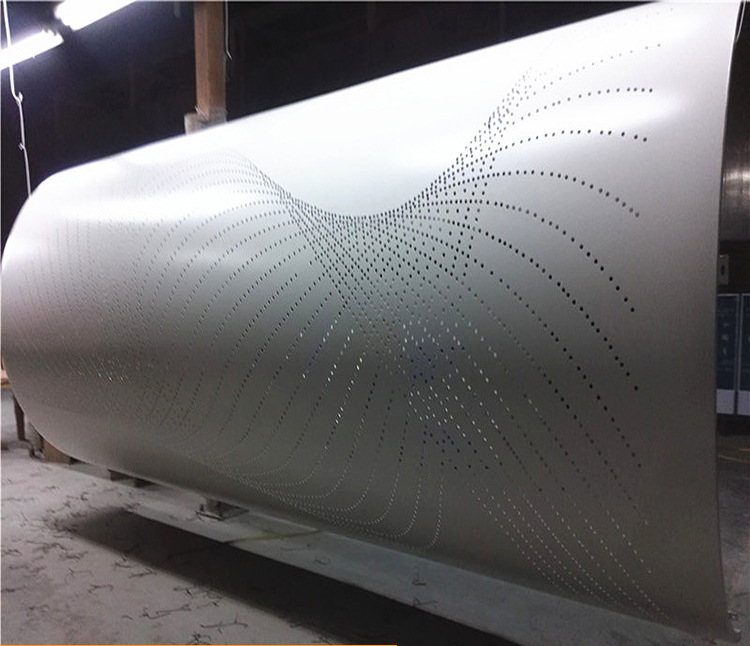

- Unlimited creativity, perforated aluminum veneer takes you to explore spatial aesthetics

Frequently asked questions

- What is the sound insulation performance of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- What is the fire resistance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Surface treatment technology and its effects on aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-26 05:01:40

- Click:0

Surface treatment technology and its effects on aluminum veneer

Abstract: This article explores the surface treatment technology of aluminum veneer and its impact on the appearance, durability, and service life of aluminum veneer.

1、 Surface coating

1. Anodizing: Anodizing is a commonly used surface treatment technique that increases the corrosion resistance and hardness of aluminum veneer by forming an oxide film on its surface. Research has shown that aluminum veneer treated with anodizing has better oxidation resistance and durability, which can effectively extend its service life.

2. Spray coating: Spray coating is another common surface treatment technique that changes the color, texture, and stain resistance of aluminum veneer by spraying paint onto its surface. Different types of spray coatings can achieve different effects, for example, fireproof coatings can improve the fire resistance level of aluminum veneers, while anti fouling coatings can reduce the pollution and cleaning frequency of aluminum veneers.

3. Fluorocarbon spraying: Fluorocarbon spraying is an advanced surface treatment technology that can provide excellent weather resistance and self-cleaning function for aluminum veneer. Research has found that aluminum veneer treated with fluorocarbon spraying has extremely strong weather resistance and can maintain good appearance and performance for a long time.

2、 Texture processing

1. Mechanical etching: By using mechanical etching technology, texture is formed on the surface of aluminum veneer, which can increase its tactile and visual effects. Different etching methods and depths can achieve various texture effects, such as wood grain, stone grain, etc. Research has shown that texture processing can improve the aesthetics and decorative effect of aluminum veneers.

2. Chemical corrosion: Chemical corrosion is a commonly used surface treatment method that produces texture effects by carrying out chemical reactions on the surface of aluminum veneer. Different corrosive solutions and treatment times can achieve various texture effects, such as clear, uniform, and fine textures. Research has found that aluminum veneers treated with chemical corrosion have better tactile and decorative effects.

3. Coating texture: During the coating process on the surface of aluminum veneer, the texture effect can be achieved by controlling the flow mode and construction process of the coating. Research has shown that coating textures can enhance the texture and visual effects of aluminum veneers, making them more decorative.

3、 Anti pollution treatment

1. Superhydrophobic coating: Superhydrophobic coating is an emerging surface treatment technology that can create high hydrophobicity on the surface of aluminum veneer, effectively resisting the erosion of water, oil, and dirt. Research has found that aluminum veneers treated with superhydrophobic coatings have excellent self-cleaning capabilities, which can reduce cleaning frequency and maintenance costs.

2. Antibacterial treatment: Antibacterial treatment on the surface of aluminum veneer can effectively prevent the growth of bacteria and fungi, improve its hygiene performance and durability. Research has shown that aluminum veneers treated with antibacterial agents have better bacterial inhibition effects and long-term stability.

3. Anti fouling coating: Anti fouling coating can form a protective film to prevent stains from adhering to the surface of aluminum veneer. Research has found that aluminum veneers treated with anti fouling coatings have strong anti pollution capabilities, are easy to clean, and are less prone to dust adhesion.

4、 Optical effect processing

1. Metallic luster: Through a special metallization process, the surface of aluminum veneer can present a metallic texture and luster. The aluminum veneer treated with metallic luster has high reflectivity and corrosion resistance, enhancing its visual appeal.

2. Color effects: By selecting spray coatings of different colors or adding special pigments, various rich color effects can be achieved. The aluminum veneer processed with color effects can increase its decorative and artistic value, meeting different architectural styles and design needs.

3. Mirror treatment: Mirror treatment is a common surface treatment technique that can create a mirror like reflection effect on the surface of aluminum veneer. The mirror treated aluminum veneer can provide high reflectivity and light environment adaptability, and is widely used in building facades and interior decoration.

5、 Summary:

In summary, the surface treatment technology of aluminum veneer has a significant impact on its appearance, durability, and service life. By selecting and applying different surface treatment techniques reasonably, the dual improvement of functionality and decoration of aluminum veneer can be achieved.

The first paragraph of the article summarizes the content

The second paragraph of the article summary content

Customer service QQ

Customer service QQ