Corporate News

Company News

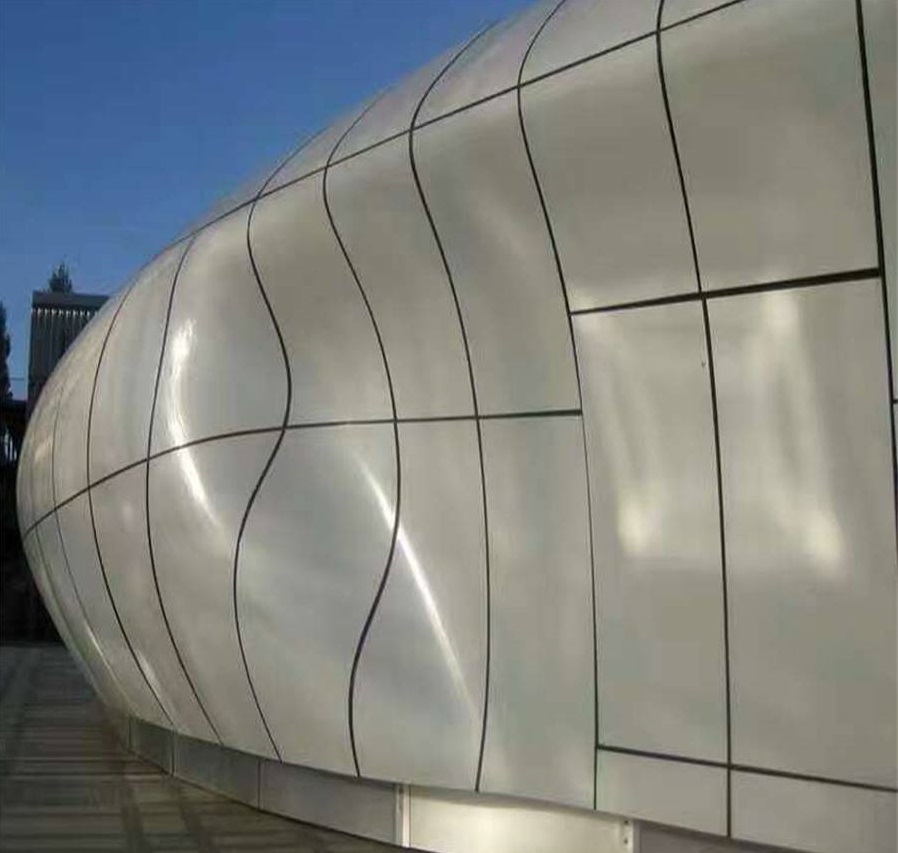

- Aluminum veneer: a fashionable choice in modern architecture

- Curtain wall aluminum veneer, creating a new style of modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer new trend curtain wall aluminum veneer, the perfect combination of beauty and practicality!

- How much do you know about aluminum veneer curtain wall: the fashionable coat of architecture?

Industry dynamics

- Aluminum veneer price - competitive landscape and advantage analysis

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer charm curtain wall aluminum veneer, the fashionable "coat" in architecture

- Aluminum veneer curtain wall: the "gorgeous coat" of modern architecture

- Punched aluminum veneer: the fashionable choice for modern architecture?

Frequently asked questions

- What are the surface treatment methods for aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- What is the fire resistance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Customization service for specifications and dimensions of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-25 05:27:05

- Click:0

Customization service for specifications and dimensions of aluminum veneer

Aluminum veneer, as a common building decoration material, has the characteristics of lightweight, durability, and fire resistance, and is widely used in the construction industry. The customization service of aluminum veneer specifications and sizes is an important link in meeting the needs of different projects. This article will provide a detailed explanation of the specification and size customization services for aluminum veneer from the following four aspects.

1、 Design requirements

1. Customized according to architectural style

The requirements for exterior wall decoration vary greatly among different architectural styles, so the specifications and dimensions of aluminum veneer need to be customized according to the specific architectural style of the project. For example, for modern minimalist style buildings, it is usually necessary to use large-sized aluminum veneers with clean and concise line designs to highlight the overall modernity. For traditional classical style buildings, it may be necessary to use small-sized aluminum veneers to simulate traditional decorative elements and reflect the historical and cultural characteristics of the building.

2. Consider functional requirements

Aluminum veneer, as a decorative material for exterior walls, not only has a beautiful appearance design, but also needs to meet certain functional requirements. For example, for high-rise buildings, wind loads and earthquake protection are important considerations. Therefore, in the customization of specifications and dimensions for aluminum veneer, it is necessary to determine the appropriate thickness and support structure based on the functional requirements of the building, to ensure that it has sufficient stability and durability.

3. Personalized customization

Nowadays, personalized design is receiving increasing attention in architectural decoration. The specification and size customization services for aluminum veneer also need to be adapted to it. By fully communicating with customers, accurately grasping their needs and preferences, and adopting customized design solutions, unique personalized effects can be achieved. For example, specific patterns or text can be printed according to customer requirements, incorporating aluminum veneer as an artistic element into the building to showcase personality and taste.

2、 Process processing

1. Cutting and shaping

The specification and size customization of aluminum veneer require precise cutting and shaping processes. According to project requirements, cut aluminum veneer into specific sized sheets and perform bending, punching, and other processing techniques to meet specific design requirements. Through advanced CNC cutting and shaping equipment, production accuracy and efficiency can be ensured.

2. Surface treatment

The surface treatment of aluminum veneer is a key step in ensuring its appearance quality and durability. According to different exterior wall decoration requirements, different surface treatment methods can be selected, such as anodizing, spraying, powder coating, etc. Through appropriate surface treatment processes, the corrosion resistance of aluminum veneer can be increased, and its color stability and glossiness can be improved.

3. Assembly and installation

After customizing the specifications and dimensions of the aluminum veneer, assembly and installation work still need to be carried out. According to specific project requirements, assemble the customized aluminum veneer panels into a complete wall system and ensure that the installation is firm and reliable. At the same time, attention should also be paid to details such as sealing gaps, connecting aluminum veneers with other building components, etc., to ensure the overall decorative effect and wind and rain sealing.

3、 Quality control

1. Strict raw material inspection

The quality of aluminum veneer is related to the aesthetics and safety of the entire building's exterior walls. Therefore, in the customization service of specifications and sizes, the selection and inspection of raw materials are crucial. It is necessary to ensure that the selected aluminum material meets relevant standards and has no obvious defects such as oxidation spots, cracks, etc.

2. Process control

Strict process control is required in every production stage to ensure the processing quality of aluminum veneer. Including the control of cutting, bending, punching and other processes, rigorous operation of surface treatment technology, and precise debugging of assembly and installation. By strictly controlling the quality requirements of each stage, it is possible to ensure that the final product meets the expected quality goals.

3. Finished product inspection and acceptance

Finally, comprehensive finished product inspection and acceptance work is required for customized aluminum veneers in terms of specifications and dimensions. Conduct visual inspection, dimensional measurement, and performance testing on each batch of aluminum veneer products to ensure they meet design requirements and standard specifications. Only through strict finished product inspection and acceptance can the quality stability and reliability of aluminum veneer be guaranteed.

4、 Service Experience

1. Full tracking service

The customization service of aluminum veneer specifications and dimensions requires the establishment of a good communication and collaboration mechanism, sufficient communication with customers, and full tracking service throughout the process. From scheme design, process processing, quality control, to installation and construction, constantly communicate with customers, answer questions, and adjust and optimize according to customer needs and feedback.

2. Timely response and after-sales service

In the process of customizing specifications and sizes, it is necessary to respond promptly to customer inquiries and requirements and provide satisfactory solutions. At the same time, it is also necessary to establish a comprehensive after-sales service system to quickly identify and solve possible problems, in order to ensure customer satisfaction and trust.

3. Technical support and guidance

Customization services for the specifications and dimensions of aluminum veneer require professional technical support and guidance. Provide customers with detailed material performance introduction, construction guidance, and maintenance information to help them better understand and use aluminum veneer products. In addition, it is also necessary to work closely with relevant designers, construction teams, etc. to jointly achieve the successful completion of the project.

summary

Customizing the specifications and dimensions of aluminum veneer is a key step in meeting the needs of different projects. By fully understanding the design requirements, fine manufacturing processes, strict quality control, and high-quality service experience, customized aluminum veneer products can be achieved to meet the personalized and quality requirements of architectural decoration.

The first paragraph of the article summarizes the content

The second paragraph of the article summary content

Customer service QQ

Customer service QQ