Industry information

Company News

- Aluminum veneer customization, creating a unique home style new trend!

- Fluorocarbon aluminum veneer: a fashionable outerwear for architecture, your new favorite for home decor

- Aluminum veneer: the fashionable choice of modern architecture, revealing its charm

- Aluminum veneer curtain wall: the beauty of architecture, with unique craftsmanship

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

Industry dynamics

- Aluminum veneer customization, creating personalized space and new fashion

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

- Aluminum veneer is the fashionable choice for modern architecture, revealing its charm behind it!

- 5 major predictions for the future prospects of the aluminum veneer market

- Market positioning of aluminum veneer prices

Frequently asked questions

- What is the installation method of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

What is the pressure resistance performance of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 20, 2025 13:39:07

- Click:0

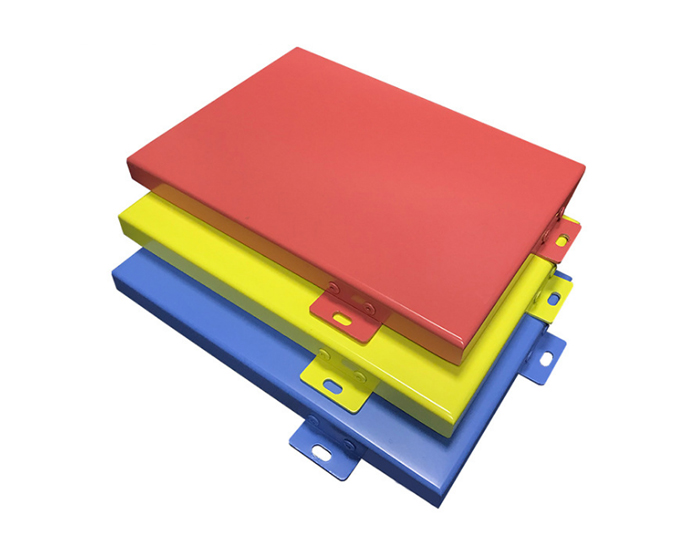

Aluminum veneer, as a common building material, its pressure resistance is also an important consideration for customers when choosing to use this product. This article will provide a detailed introduction to the pressure resistance performance of aluminum veneer.

1、 Material characteristics

Aluminum veneer is mainly made of processed aluminum alloy sheets, which have the characteristics of lightweight, high strength, and corrosion resistance. The strength and hardness of aluminum alloy sheet directly affect the pressure resistance of aluminum veneer. Generally speaking, the higher the strength and hardness of aluminum alloy sheets, the better the pressure resistance of aluminum veneers.

2、 Production process

The production process of aluminum veneer is also one of the important factors affecting its pressure resistance performance. In the production process, advanced production technology and equipment are required to ensure the quality and performance of aluminum veneer. For example, in the production process of aluminum veneer, cold rolling, hot rolling and other processes can be used to improve the strength and hardness of aluminum veneer, thereby enhancing its pressure resistance. Surface treatment processes such as anodizing can also be used to increase the corrosion resistance and wear resistance of aluminum veneer.

3、 Thickness and shape

The thickness and shape of aluminum veneer are also factors that affect its pressure resistance performance. Generally speaking, the thicker the aluminum veneer, the better its pressure resistance performance. The shape of aluminum veneer also affects its pressure resistance performance. For example, in the decoration of building exterior walls, thicker aluminum veneers are usually used to withstand external forces such as wind pressure and snow pressure, thereby improving their pressure resistance performance.

4、 Installation method

The installation method of aluminum veneer is also one of the factors affecting its pressure resistance performance. During the installation process, attention should be paid to the connection and fixing methods between the aluminum veneer and the support. If the connection method is unreasonable or not firmly fixed, it will affect the pressure resistance performance of the aluminum veneer. Suitable connectors and fasteners need to be used during the installation process to ensure the stability and pressure resistance of the aluminum veneer.

5、 Maintenance and upkeep

The maintenance of aluminum veneer is also one of the important means to affect its pressure resistance performance. During use, it is necessary to regularly inspect and maintain the aluminum veneer, including cleaning, moisture prevention, sun protection, and other aspects. If damage or aging is found on the aluminum veneer, it should be repaired or replaced in a timely manner to ensure its pressure resistance and service life.

The pressure resistance of aluminum veneer is influenced by various factors, including material properties, production processes, thickness and shape, installation methods, and maintenance. Enterprises need to pay attention to product quality and service level, and actively respond to national environmental policies and requirements, providing customers with healthier and more environmentally friendly building decoration materials. The government also needs to strengthen the supervision and management of the aluminum veneer industry to promote its sustainable development.

Customer service QQ

Customer service QQ