Industry information

Company News

- Fluorocarbon aluminum veneer: creating a new style of modern architecture

- Fluorocarbon aluminum veneer: a fashionable "outerwear" in modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer: the "green clothing" of modern architecture

- Aluminum veneer curtain wall: the beauty of architecture, the charm of details

Industry dynamics

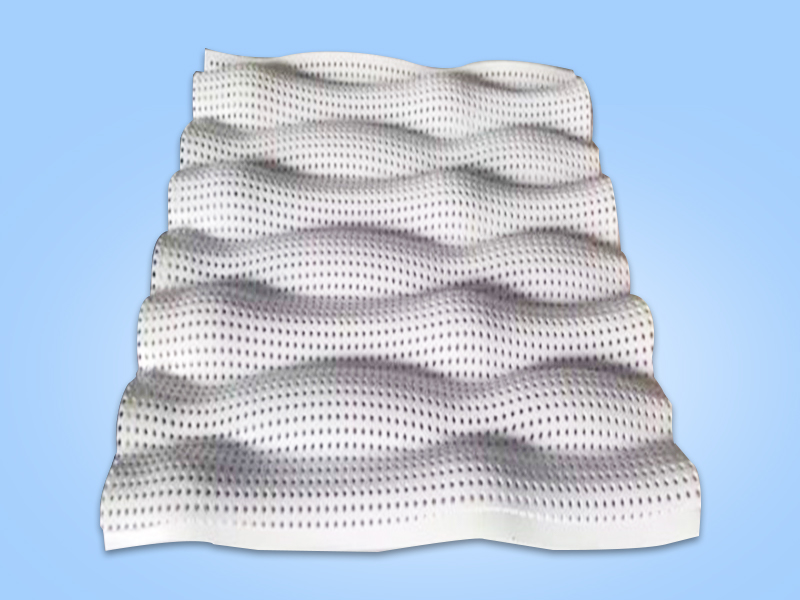

- Punched aluminum veneer: the fashionable choice in modern architecture?

- Aluminum veneer curtain wall: the "green coat" of modern architecture

- Aluminum veneer curtain wall: an analysis of the charm of the "coat" of modern architecture

- 5 directions of innovative design concept for aluminum veneer

- Aluminum veneer customization, creating personalized space and new fashion

Frequently asked questions

- What is the sound insulation performance of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- What are the common methods for surface treatment of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to improve the sound insulation performance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Understand the production process and installation process of fluorocarbon aluminum veneer curtain wall

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-05 05:05:01

- Click:0

Fluorocarbon aluminum veneer curtain wall is a widely used material in the field of building exterior wall decoration in recent years, which has many advantages and characteristics. Understanding the manufacturing process and installation process of fluorocarbon aluminum veneer curtain walls can help us better choose and use this material. Below, we will provide a detailed introduction for everyone.

1、 Production process

The production process of fluorocarbon aluminum veneer curtain wall mainly includes the following steps:

1. Aluminum processing: Firstly, high-strength aluminum alloys need to be cut, bent, and processed to meet the different shape and size requirements of fluorocarbon aluminum veneer curtain walls.

2. Fluorocarbon coating treatment: The processed aluminum surface is treated with fluorocarbon coating to enhance its corrosion resistance and aesthetics.

3. Stamping forming: Stamping the aluminum material coated with fluorocarbon coating to form various shapes and sizes required for fluorocarbon aluminum veneer curtain walls.

2、 Installation process

The installation process of fluorocarbon aluminum veneer curtain wall mainly includes the following steps:

1. Measurement and positioning: Conduct measurement and positioning on the exterior wall of the building to determine the position and size of the fluorocarbon aluminum veneer curtain wall.

2. Installation of keel: Install keels on the exterior walls of buildings to support the structure of fluorocarbon aluminum veneer curtain walls.

3. Install connectors: Install connectors on the keel and connect the fluorocarbon aluminum veneer to the keel.

4. Apply sealant: Apply sealant at the interface between the fluorocarbon aluminum veneer and the keel to ensure its firmness and reliability.

5. Inspection and acceptance: Finally, inspect and accept the fluorocarbon aluminum veneer curtain wall to ensure that it meets the design requirements and construction standards.

3、 Precautions

When making and installing fluorocarbon aluminum veneer curtain walls, the following points should be noted:

1. Ensure that the quality and performance of the materials meet the requirements and avoid using inferior products.

During the installation process, it is necessary to strictly follow the operating procedures to ensure safety and reliability.

3. When applying sealant, pay attention to the color and material of the sealant to avoid pollution or damage to the building.

Understanding the manufacturing process and installation process of fluorocarbon aluminum veneer curtain walls can help us better choose and use this material. Attention should also be paid to some details during the production and installation process to ensure its quality, safety, and reliability.

Customer service QQ

Customer service QQ