Industry information

Company News

- The fashion journey of fluorocarbon aluminum veneer: a new favorite for weather resistance

- Aluminum veneer curtain wall: the beauty of architecture, with unique craftsmanship

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Exploring the unique charm of fluorocarbon aluminum veneer

- Aluminum veneer curtain wall, the new darling of modern architecture!

Industry dynamics

- Aluminum veneer curtain wall: the beauty of architecture lies in this piece of aluminum light

- Manufacturing process of fluorocarbon coated aluminum veneer

- Aluminum veneer curtain wall, the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating a unique spatial aesthetic

- Exploring innovative design and style evolution of 2.5mm aluminum veneer for exterior walls

Frequently asked questions

- What is the insulation performance of aluminum veneer?

- What is the installation method of aluminum veneer?

- What are the common methods for surface treatment of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

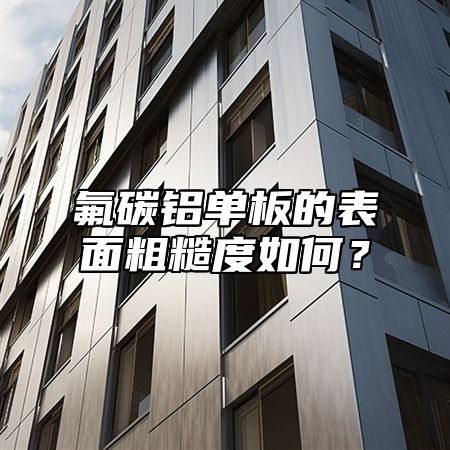

What is the surface roughness of fluorocarbon aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-25 09:55:37

- Click:0

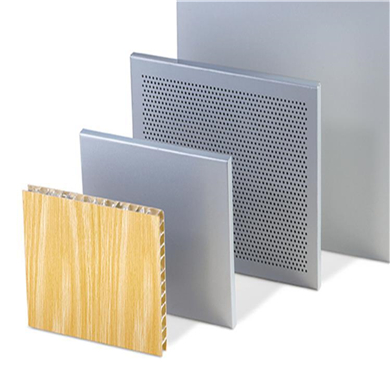

Fluorocarbon aluminum veneer is a widely used building material in various fields such as construction, billboards, curtain walls, etc. The surface roughness is one of the important concerns for consumers. The surface roughness of fluorocarbon aluminum veneer will be described in detail below.

1. Definition of surface roughness

Surface roughness refers to the degree of protrusion or depression on the surface of a material. Generally speaking, materials with higher surface roughness can increase friction and slip resistance, thereby improving safety and comfort.

1. Surface roughness of fluorocarbon aluminum veneer

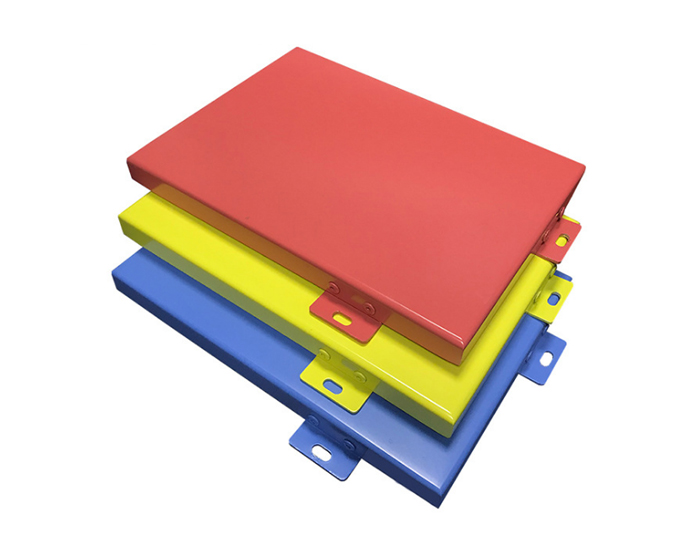

The surface roughness of fluorocarbon aluminum veneer is related to factors such as its material and production process. High quality fluorocarbon aluminum veneer is usually made of high-strength aluminum alloy material, which is precision processed and treated to form a hard oxide film on its surface, thereby improving its hardness and wear resistance. Fluorocarbon aluminum veneer can also improve its surface roughness through polishing and other processes to enhance its slip resistance and aesthetics.

It should be noted that the surface roughness of fluorocarbon aluminum veneer is not absolute, and its performance is affected by various factors such as material quality, usage environment, maintenance, etc. When using fluorocarbon aluminum veneer, it is necessary to choose and design according to the specific situation, and follow the manufacturer's instructions and maintenance suggestions to ensure the service life and stable performance of fluorocarbon aluminum veneer.

Fluorocarbon aluminum veneer has a certain surface roughness, which can be improved in terms of slip resistance and aesthetics through processes such as polishing. However, the specific surface roughness still needs to be evaluated and determined based on factors such as material characteristics and production processes. Consumers should choose fluorocarbon aluminum veneer products that meet the standards and follow the manufacturer's instructions and maintenance recommendations to ensure the service life and stable performance of fluorocarbon aluminum veneer. Attention should also be paid to the characteristics of materials and structural limitations during design and installation to ensure that the construction effect meets the requirements.

Customer service QQ

Customer service QQ