Industry information

Company News

- Exploring perforated aluminum veneer: the new darling of fashionable building materials!

- Unveiling the 'weather resistance power' of fluorocarbon aluminum veneer

- Punched aluminum veneer: a hidden master of creative decoration

- Punched aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer, the fashionable "lightweight" new favorite in the construction industry

Industry dynamics

- Aluminum veneer curtain wall: the beauty of architecture, details can be seen in the real chapter

- Unveiling Aluminum Veneers for Curtain Walls: Metal Fashion in Modern Architecture

- Brushed aluminum veneer ceiling creates comfortable home space

- High quality shaped aluminum veneer installation

- Using punched aluminum veneer to create a modern architectural style

Frequently asked questions

- What is the fire resistance of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- What is the sound insulation performance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- What is the installation method of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

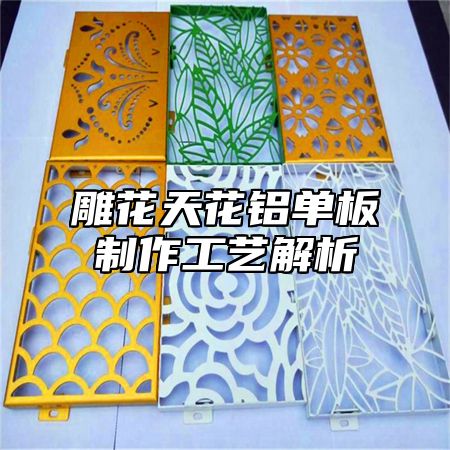

Analysis of the production process of carved ceiling aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 20, 2025 16:31:23

- Click:0

Carved ceiling aluminum veneer is a very popular modern architectural decoration material, and its unique design and production process can add unique charm to buildings. Next, let's introduce in detail the production process of carved ceiling aluminum veneer.

1、 Material preparation

Before making carved ceiling aluminum veneer, it is necessary to prepare the required materials and tools, including aluminum alloy sheets, carving machines, cutting tools, screws, nuts, expansion bolts, drills, hammers, level gauges, etc.

2、 Design phase

In the design phase, it is necessary to design according to the customer's needs, determine patterns and color matching schemes. Then design and manufacture the aluminum veneer according to the design plan.

3、 Production stage

1. Carving processing: Use a carving machine to carve aluminum alloy sheets to form the desired patterns and lines. At the same time, it is necessary to use cutting tools for fine machining and polishing to ensure its quality and effectiveness.

2. Surface treatment: In order to improve the weather resistance and corrosion resistance of aluminum alloy sheets, surface treatment is required. Common surface treatment methods include anodizing, electrophoretic coating, powder coating, etc. These processing methods can form a dense oxide film or coating on the surface of aluminum alloy sheets, thereby improving their durability and aesthetics.

3. Installation accessories: When using carved ceiling aluminum veneer, various installation accessories such as screws, nuts, expansion bolts, drills, hammers, level gauges, etc. are also required. These accessories can ensure the flatness and orientation of the aluminum veneer, ensuring its aesthetics and practicality.

4、 Precautions

During the use of carved ceiling aluminum veneer, attention should also be paid to some details, such as preventing damage and contamination to the aluminum veneer. Attention should also be paid to safety issues, especially when using tools such as drills and hammers, which require wearing protective goggles and gloves.

The production process of carved ceiling aluminum veneer requires multiple stages including material preparation, design, and manufacturing. From the above analysis, it can be seen that there are obvious advantages in material preparation, design, production, and installation when making carved ceiling aluminum veneer. In the future development, with the continuous progress of technology and the continuous development of society, carved ceiling aluminum veneer will play a more important role.

Customer service QQ

Customer service QQ