Industry information

Company News

- Unveiling the "Appearance" and "Strength" of Aluminum Veneers for Curtain Walls

- Aluminum veneer curtain wall: the new darling of modern architecture!

- Customized aluminum veneer, creating a new choice for personalized space!

- Aluminum veneer: the new darling of the construction industry, what do you know about it?

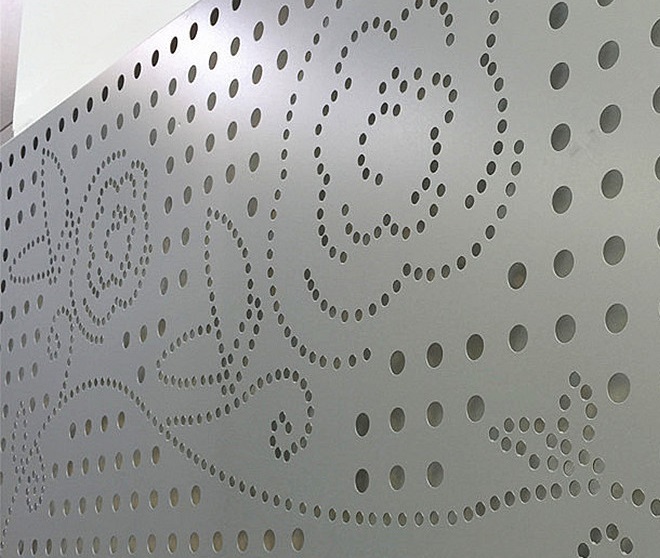

- Aluminum veneer punching, infinite creativity, a new chapter of architectural beauty!

Industry dynamics

- Aluminum veneer curtain wall: the new darling of modern architecture, how much do you know?

- Curtain wall aluminum veneer, the fashionable choice for modern architecture?

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

- Aluminum veneer curtain wall, the "fashionable coat" of modern architecture

- Will the use of aluminum veneer affect the aesthetic appearance of buildings?

Frequently asked questions

- How to improve the insulation performance of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- What are the common methods for surface treatment of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Analysis of Manufacturing Process for Twisted Aluminum Veneer with Wrapped Columns

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-13 22:23:07

- Click:0

Aluminum veneer is a widely used material in architectural decoration, and its advantages such as lightweight, high strength, and easy processing are highly favored by architects and designers. The twisted aluminum veneer with wrapped columns is a special type of aluminum veneer that is innovatively designed and manufactured based on aluminum veneer. Its unique shape and visual effects have attracted much attention in the field of architectural decoration. This article will provide a detailed introduction to the manufacturing process of twisted aluminum veneer with wrapped columns.

1、 Raw material preparation

The manufacturing of twisted aluminum veneer requires the use of raw materials such as aluminum veneer, angle iron, screws, etc. The quality and thickness of aluminum veneer are key factors affecting product performance and appearance. When selecting raw materials, it is necessary to screen and test according to product requirements.

2、 Making molds

The shape and structure of twisted aluminum veneer wrapped in columns are relatively complex, requiring the production of specialized molds. The production of molds needs to consider factors such as product size, shape, and connection methods to ensure the quality and accuracy of the final product.

3、 Cutting aluminum veneer

After making the mold, it is necessary to cut the aluminum veneer. Professional cutting equipment and techniques are required during cutting to ensure cutting accuracy and surface quality. Attention should also be paid to parameters such as length, width, and thickness of aluminum veneer to meet subsequent processing requirements.

4、 Bent aluminum veneer

After cutting the aluminum veneer, it needs to be bent. When bending, professional equipment and techniques are required to ensure that the bending degree and angle meet the design requirements. Attention should also be paid to the overall integrity and stability of the aluminum veneer to avoid problems such as deformation or cracking.

5、 Welding and polishing

After completing the bending process, it is necessary to weld and polish the aluminum veneer. High quality welding materials and techniques are required during welding to ensure the quality and strength of the weld seam. Professional equipment and techniques are required for polishing to ensure the smoothness and aesthetics of the surface.

6、 Installation and maintenance

After completing the welding and polishing process, it is necessary to install and maintain the twisted aluminum veneer wrapped around the column. During installation, it is necessary to follow the design requirements and installation specifications to ensure the accuracy and stability of the installation. Regular inspection and cleaning of the product surface are required during maintenance to maintain its aesthetics and service life.

The manufacturing process of twisted aluminum veneer with wrapped columns is a complex process that requires multiple stages of processing and treatment to be completed. Through continuous research and development, we can continuously improve the manufacturing process and technological level of twisted aluminum veneer for column wrapping, providing more choices and possibilities for the building decoration industry.

Customer service QQ

Customer service QQ