Industry information

Company News

- Punched aluminum veneer: a fashionable choice for modern architecture, revealing its unique charm!

- Aluminum veneer curtain wall, a new chapter in the beauty of architecture

- Punched aluminum veneer: a fashionable element in modern architecture

- Aluminum veneer: creating a new style of modern architecture

- Punched aluminum veneer: the new favorite of fashionable architecture and the revolution of aluminum application

Industry dynamics

- Production cost and price trend of aluminum veneer

- What are the advantages of aluminum veneer compared to traditional building materials?

- Customize exquisite 3mm aluminum veneer carving effect

- Beautiful and atmospheric fluorocarbon carved aluminum veneer creates a new trend in the furniture industry

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

Frequently asked questions

- How to improve the sound insulation performance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

- What is the sound insulation performance of aluminum veneer?

- What is the fire resistance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Analysis of Production Process for 3mm Carved Aluminum Veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-12 22:46:33

- Click:0

3mm carved aluminum veneer is a building material with unique decorative effects, and its production process is very complex. Below is a detailed introduction to the production process of 3mm carved aluminum veneer.

1、 Raw material preparation

1. Aluminum alloy sheet

The main raw material for 3mm carved aluminum veneer is aluminum alloy sheet, and high-quality aluminum alloy materials need to be selected to ensure the quality and performance of the product.

2. Mold

The mold is a key component for producing 3mm carved aluminum veneer, and precise molds need to be made according to design requirements.

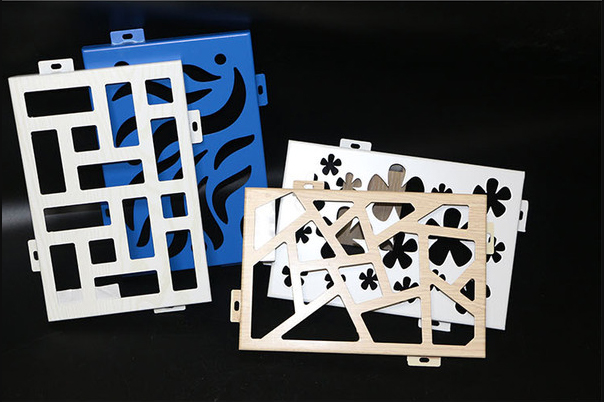

2、 Cutting and processing

1. Laser cutting

Cut the aluminum alloy sheet through a laser cutting machine to obtain the desired size and shape.

2. Punching processing

Punch the cut aluminum alloy sheet using a punching machine to obtain the desired perforation rate and aperture size.

3、 Surface treatment

1. Anodizing treatment

After punching processing, the aluminum alloy sheet needs to be anodized to enhance its corrosion resistance and aesthetics. The processing includes steps such as electrolysis, cleaning, and staining.

2. Spray treatment

If spraying treatment is required, the anodized aluminum alloy sheet needs to be sent to the spraying workshop for spraying treatment. The processing includes steps such as primer and topcoat.

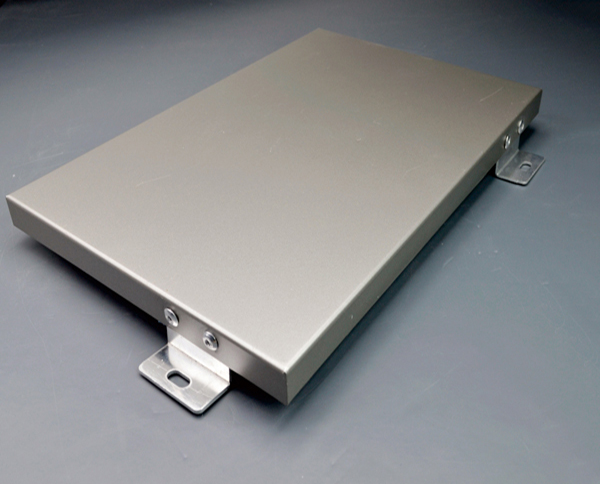

4、 Installation and construction

1. Install the keel

Before installing 3mm carved aluminum veneer, it is necessary to first install the keel and fix it to the structure of the building.

2. Install 3mm carved aluminum veneer

Install and construct 3mm carved aluminum veneer that has undergone surface treatment according to design requirements, and adjust and trim it to ensure its decorative effect and structural safety.

The production process of 3mm carved aluminum veneer is very complex and requires multiple stages of processing and treatment to be finally completed. Only through strict production processes and quality control can high-quality 3mm carved aluminum veneer be produced, adding unique artistic charm to buildings.

Customer service QQ

Customer service QQ