Corporate News

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer: the "lightweight fashion expert" in the construction industry

- Aluminum veneer, the fashionable 'outerwear' in modern architecture

- Aluminum veneer customization, creating the art of personalized space

- Aluminum veneer curtain wall: the "silver coat" of modern architecture

Industry dynamics

- Aluminum veneer curtain wall: the fashionable coat of architecture, your new aesthetic favorite

- Innovative application of aluminum veneer in indoor decoration

- Can fluorocarbon aluminum veneer be customized in thickness?

- Unveiling Aluminum Veneers for Curtain Walls: Metal Fashion in Modern Architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

Frequently asked questions

- What is the sound insulation performance of aluminum veneer?

- What is the fire resistance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- What are the surface treatment methods for aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

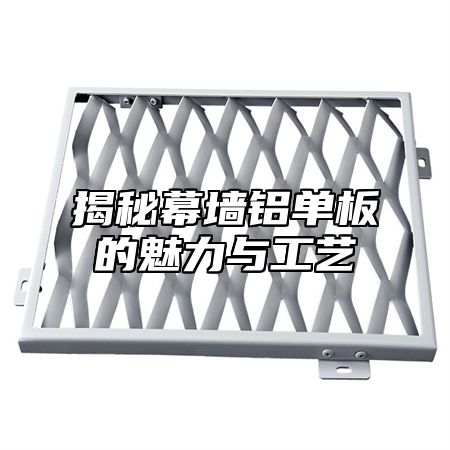

Unveiling the Charm and Craftsmanship of Aluminum Veneers for Curtain Walls

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 28, 2025 08:00:05

- Click:0

hello everyone! Today we will talk about this curtain wall aluminum veneer, which is a common good thing in modern architecture. You may often see those shiny "coats" on high-rise buildings, which is actually the time when aluminum veneers show off their power.

We need to talk about the charm of aluminum veneer. This thing is like putting a fashionable coat on the building, both beautiful and practical. Imagine walking on the streets of a city and looking up, you'll see towering skyscrapers with mirror like surfaces that give off a sense of high-end grandeur. This is all thanks to aluminum veneer, which not only has a good decorative effect, but also protects the building from wind and rain.

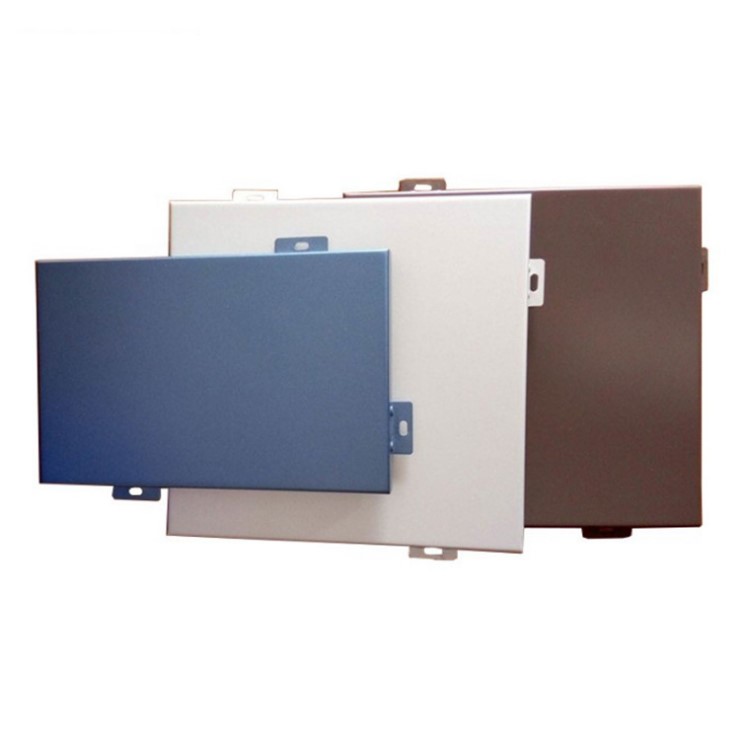

Aluminum veneer, as the name suggests, is made of aluminum plate. It has the advantages of being lightweight, corrosion-resistant, and easy to process. In modern architecture, the application of aluminum veneer is becoming increasingly widespread, not only for curtain walls, but also for interior decoration, ceilings, partitions, and so on. It has a rich variety of colors, including white, gray, gold, etc., which can be customized according to the designer's requirements, making the building more personalized and diverse.

When it comes to craftsmanship, there is a need for attention to detail. The production process of aluminum veneer is divided into the following steps:

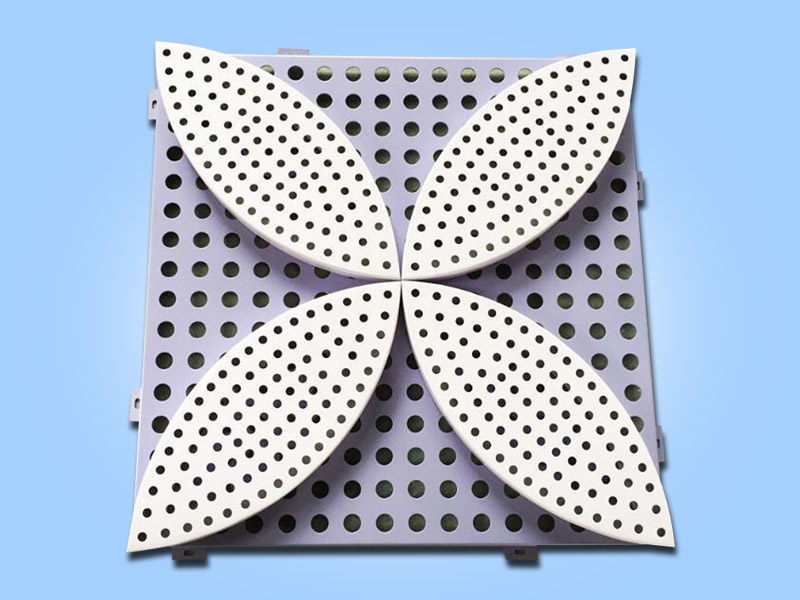

1. Aluminum plate cutting: Cut the aluminum plate into the required size and shape according to the requirements of the design drawings.

2. Surface treatment: In order to improve the corrosion resistance and decorative effect of aluminum veneer, surface treatment such as painting, baking paint, rolling coating, etc. is usually carried out.

3. Drilling and bending: Drill holes on the surface of the aluminum plate for easy installation and fixation, and then bend the aluminum plate into shape.

4. Assembly: Assemble the perforated and bent aluminum plates into curtain wall panels, and perform welding, screw fixation, etc.

5. Decoration: Carving, printing and other decorative treatments on the surface of aluminum veneer.

In this production process, the quality and craftsmanship of aluminum veneer are crucial. Good aluminum veneer not only has a beautiful appearance, but also is durable and environmentally friendly. How to determine the quality of aluminum veneer?

Look at the material. High quality aluminum veneers should be made of high-purity and high-strength aluminum materials to ensure their performance.

Look at the surface treatment. Good aluminum veneer has exquisite surface treatment technology, uniform color, and is not easy to fade.

Check the machining accuracy. The higher the processing accuracy of aluminum veneer, the better the effect after installation.

Check the welding quality. Welding is a crucial step in the production process of aluminum veneer, and the quality of welding directly affects the overall performance of the aluminum veneer.

We also need to talk about the drawbacks of aluminum veneer. Although aluminum veneer has many advantages, there are also some shortcomings. Aluminum veneer is prone to deformation in high temperature environments and has relatively weak impact resistance. The installation and disassembly of aluminum veneer are quite complicated and require professional personnel to operate.

Is there any way to make up for these shortcomings? Of course there is! By strengthening the internal structure of aluminum veneer, its impact resistance can be improved; Add a protective film on the surface of the aluminum veneer to prevent high-temperature deformation; During the installation process, choose the appropriate fixing method to ensure the stability and safety of the aluminum veneer.

Aluminum veneer plays an important role in modern architecture. It not only enhances the aesthetic appeal of buildings, but also extends their lifespan. When choosing aluminum veneer, attention should also be paid to quality and craftsmanship to ensure the overall effect of the building.

After talking a lot, I suddenly remembered an interesting story. I remember when I was a child, there was a newly built residential building in front of my house. I thought the building was really beautiful and envied the people living inside. I grew up and started working in the construction industry, only to realize that the exterior of that building was made of aluminum veneer. Thinking about myself back then, I was truly pure and ignorant!

Alright, that's all for today's sharing. If you have any further questions about aluminum veneer or want to learn more about the construction industry, please feel free to leave a comment in the comments section! See you next time!

Customer service QQ

Customer service QQ