Industry information

Company News

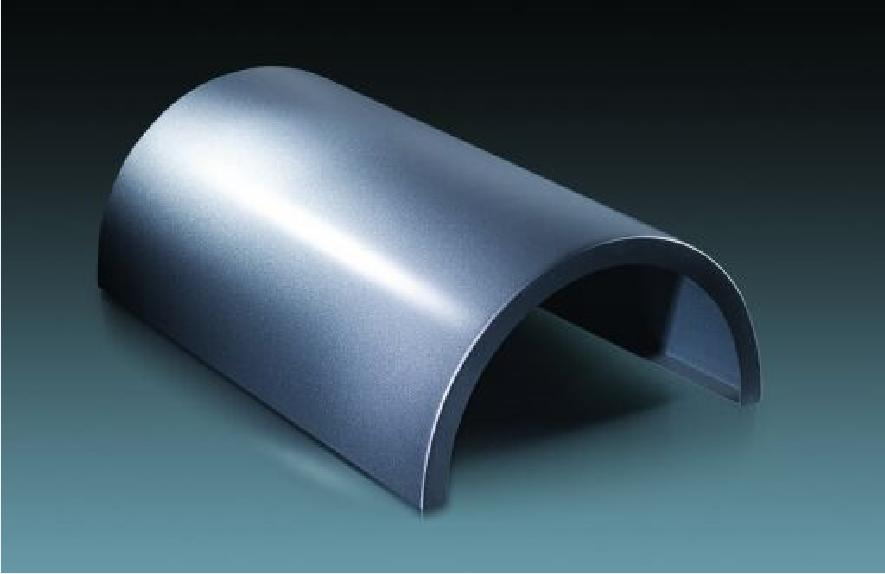

- Aluminum veneer curtain wall: the "lightweight canvas" of architectural art

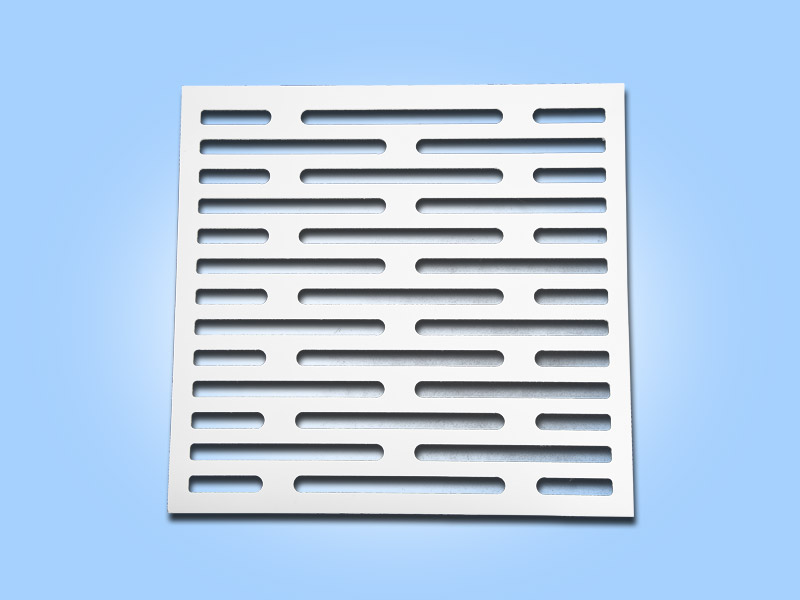

- Exploring perforated aluminum veneer: the new darling of fashionable building materials!

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum plate punching, unlimited creativity, new architectural style!

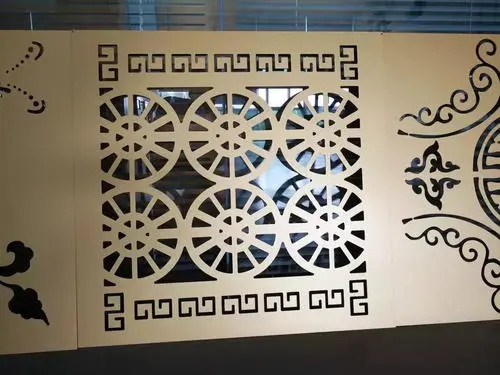

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Punched aluminum veneer: a fashionable choice in modern architecture, versatile with one board!

- Fluorocarbon aluminum veneer: the fashionable new darling of the aluminum industry

- 5 directions of innovative design concept for aluminum veneer

- Aluminum veneer curtain wall: the "coat" of modern architecture

- Aluminum veneer customization, creating the art of personalized space

Frequently asked questions

- What is the fire resistance of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- What are the common methods for surface treatment of aluminum veneer?

- How to improve the fire resistance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Anti rust treatment method for aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 27, 2025 14:51:24

- Click:0

Aluminum veneer, as a common building material, is easily affected by oxidation, corrosion, and other factors on its surface, which can affect its appearance and service life. Rust prevention treatment of aluminum veneer is one of the important measures to ensure its quality and performance. Next, let's take a detailed look at the rust prevention treatment methods for aluminum veneer.

1、 Surface treatment

The surface treatment of aluminum veneer is the basis for preventing rust and corrosion, usually including the following methods:

1. Anodizing: Place aluminum veneer in an electrolyte solution to form an oxide film through electrolytic reaction, thereby improving its corrosion resistance and decorative properties.

2. Fluorocarbon paint: Coating a layer of fluorocarbon paint on the surface of aluminum veneer can provide good anti-corrosion protection effect.

3. Powder coating: Spraying a layer of powder coating on the surface of aluminum veneer can improve its corrosion resistance and decorative properties.

2、 Chemical treatment

In addition to surface treatment, chemical treatment can also be used to prevent rust on aluminum veneer. Common chemical treatment methods include:

1. Phosphate method: Coating a layer of phosphate solution on the surface of aluminum veneer to form a phosphate film, thereby improving its corrosion resistance.

2. Sulfuric acid method: Apply a layer of sulfuric acid solution on the surface of aluminum veneer to form a sulfuric acid film, thereby improving its corrosion resistance.

3、 Electrochemical protection

Electrochemical protection is a method of rust prevention for aluminum veneer using electrochemical principles. Common electrochemical protection methods include:

1. Electrophoretic coating: Place the aluminum veneer in an electrophoresis tank, apply a negative charge to its surface through the action of an electric field, and then the positively charged particles in the coating are adsorbed on the surface to form a coating, thereby improving its corrosion resistance.

2. Electroplating: Covering a metal coating on an aluminum veneer to form a protective film, thereby improving its corrosion resistance. Common metal coatings include zinc, chromium, copper, etc.

4、 Conclusion

By surface treatment, chemical treatment, or electrochemical protection of aluminum veneer, its corrosion resistance and decorative properties can be effectively improved. Choosing the appropriate rust prevention treatment method can ensure that the quality and performance of aluminum veneer meet relevant requirements, providing reliable material guarantee for building decoration.

Customer service QQ

Customer service QQ