Industry information

Company News

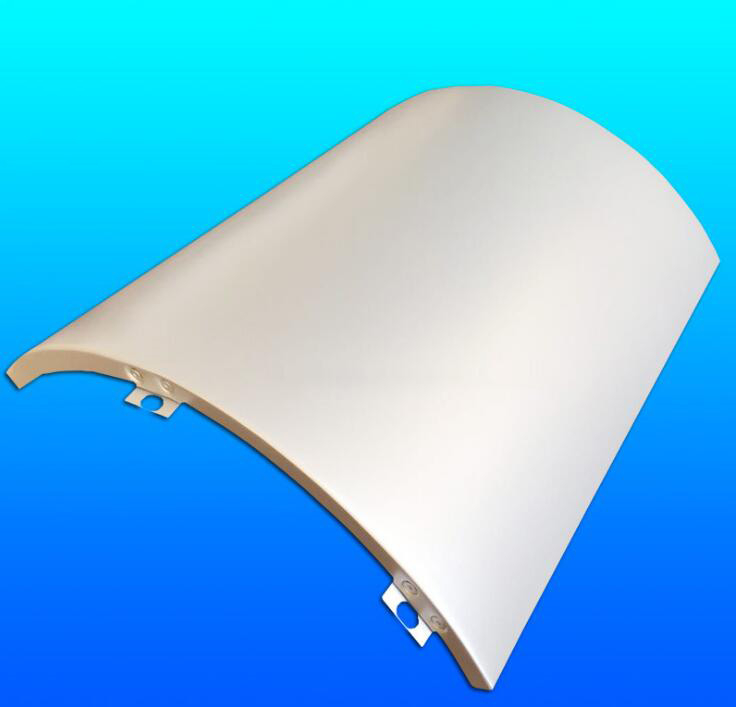

- Aluminum veneer: the new favorite of the construction industry and the secret weapon of the light luxury trend!

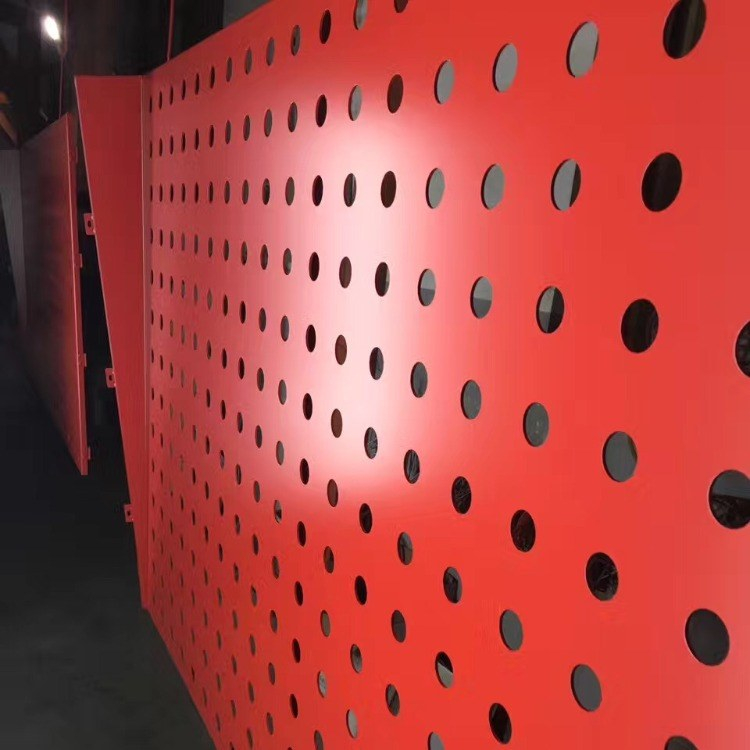

- Punched aluminum veneer: a fashionable choice for modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization, creating exclusive space aesthetics

- Strength and seismic performance of aluminum veneer

Industry dynamics

- Customized aluminum veneer makes buildings more in line with people's cultural connotations

- Aluminum veneer, the aesthetic secret of modern architecture!

- Aluminum veneer customization, creating a new trend of personalized space

- Classification and specifications of aluminum veneer, how to better choose aluminum veneer

- Analysis of Market Competitiveness of Aluminum Veneer Prices

Frequently asked questions

- What are the common methods for surface treatment of aluminum veneer?

- What is the sound insulation performance of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- What is the installation method of aluminum veneer?

- How to improve the insulation performance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Installation and maintenance guide for 2.5mm aluminum veneer in buildings

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 2, 2025 10:41:47

- Click:0

The installation and maintenance of 2.5mm aluminum veneer in buildings are key to ensuring their service life and aesthetic appearance. This article will provide a detailed guide for the installation and maintenance of 2.5mm aluminum veneer in buildings, to help readers better use and maintain this material.

1、 Preparation before installation

Before installing the 2.5mm aluminum veneer in the building, the following preparations need to be made:

1. Determine installation location: Based on the design drawings and actual requirements, determine the installation location of the 2.5mm aluminum veneer in the building.

2. Measurement dimensions: Use measuring tools to measure the length, width, height, and other dimensions of the 2.5mm aluminum veneer in the building to ensure that it matches the design drawings.

3. Material inspection: Check the quality of the 2.5mm aluminum veneer in the building to ensure there are no obvious defects or damage.

2、 Installation steps

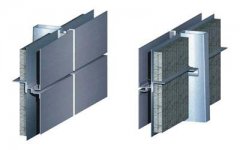

The installation steps for building 2.5mm aluminum veneer are as follows:

1. Wire marking and positioning: Mark the installation position to determine the position and size of the 2.5mm aluminum veneer in the building.

2. Punching and fixing: Use tools such as electric drills to drill holes at the snap line position, and use screws to fix the 2.5mm aluminum veneer of the building to the wall or other substrate.

3. Adjust position: Check if the position of the 2.5mm aluminum veneer in the building is correct, and adjust it if there is any deviation.

3、 Maintenance methods

In order to ensure the service life and aesthetics of the 2.5mm aluminum veneer in the building, regular maintenance work is required. Here are some common maintenance methods:

1. Cleaning: Regularly use clean water or neutral detergent to clean the surface of 2.5mm aluminum veneer in the building, removing dust and dirt.

2. Avoid scratching: Avoid using hard objects or sharp objects to scratch the surface of the 2.5mm aluminum veneer of the building to avoid scratching or damaging the surface.

3. Pay attention to moisture prevention: Avoid exposing the 2.5mm aluminum veneer of the building to a humid environment for a long time to prevent rusting or deformation.

4、 Precautions

When installing and maintaining 2.5mm aluminum veneer panels in buildings, the following points should be noted:

1. Ensure that construction personnel have the appropriate skills and experience to ensure installation quality and effectiveness.

During maintenance, it is necessary to use appropriate cleaning agents and tools to avoid damage to the 2.5mm aluminum veneer of the building.

During maintenance, it is necessary to comply with relevant safety regulations and operating procedures to ensure construction safety.

Customer service QQ

Customer service QQ