Industry information

Company News

- Aluminum veneer decoration, creating a new trend of fashionable home decor!

- Curtain wall aluminum veneer: creating a new style of modern architecture

- Aluminum veneer curtain wall: a fashionable choice for modern architecture

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Aluminum veneer curtain wall, the new aesthetic favorite of modern architecture

- What are the advantages of using aluminum veneer in modern architecture?

- Aluminum veneer curtain wall adds a touch of fashion color to the building

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

- Curtain wall aluminum veneer: a fashionable outerwear for modern architecture

Frequently asked questions

- What is the sound insulation performance of aluminum veneer?

- What are the common methods for surface treatment of aluminum veneer?

- What is the installation method of aluminum veneer?

- What is the insulation performance of aluminum veneer?

- What is the fire resistance of aluminum veneer?

contact us

Mobile phone: 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City

Unique architectural carving material - aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-24 20:16:47

- Click:0

Aluminum veneer, as a unique architectural carving material, has many advantages and applications. It can be used not only for architectural decoration, but also for industrial, transportation and other fields. This article will provide a detailed introduction to the unique features of aluminum veneer and its applications in the field of construction.

Aluminum veneer has advantages such as lightweight, high strength, and corrosion resistance. Compared to traditional building materials such as stone and wood, aluminum veneer is lighter, easier to handle and install. It also has very high strength and can withstand significant pressure and wind force. Aluminum veneer also has good corrosion resistance, which can resist the erosion of natural factors such as oxidation and corrosion.

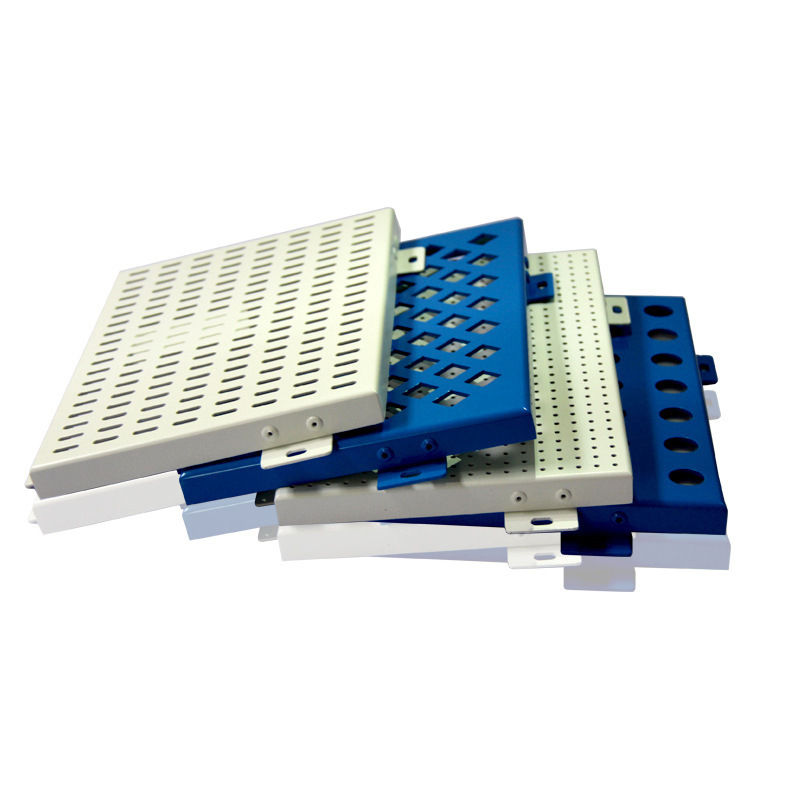

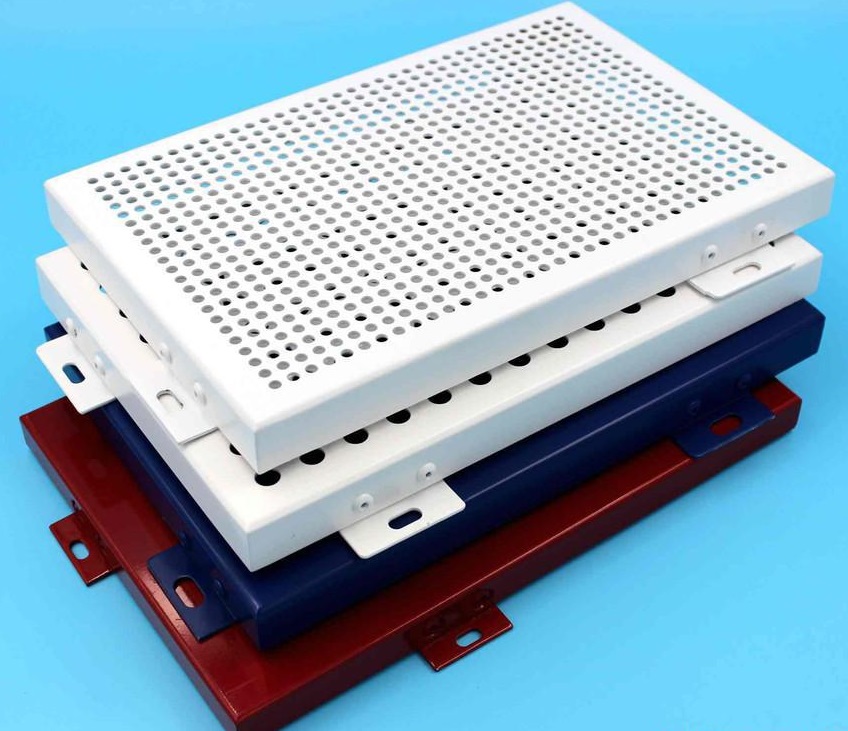

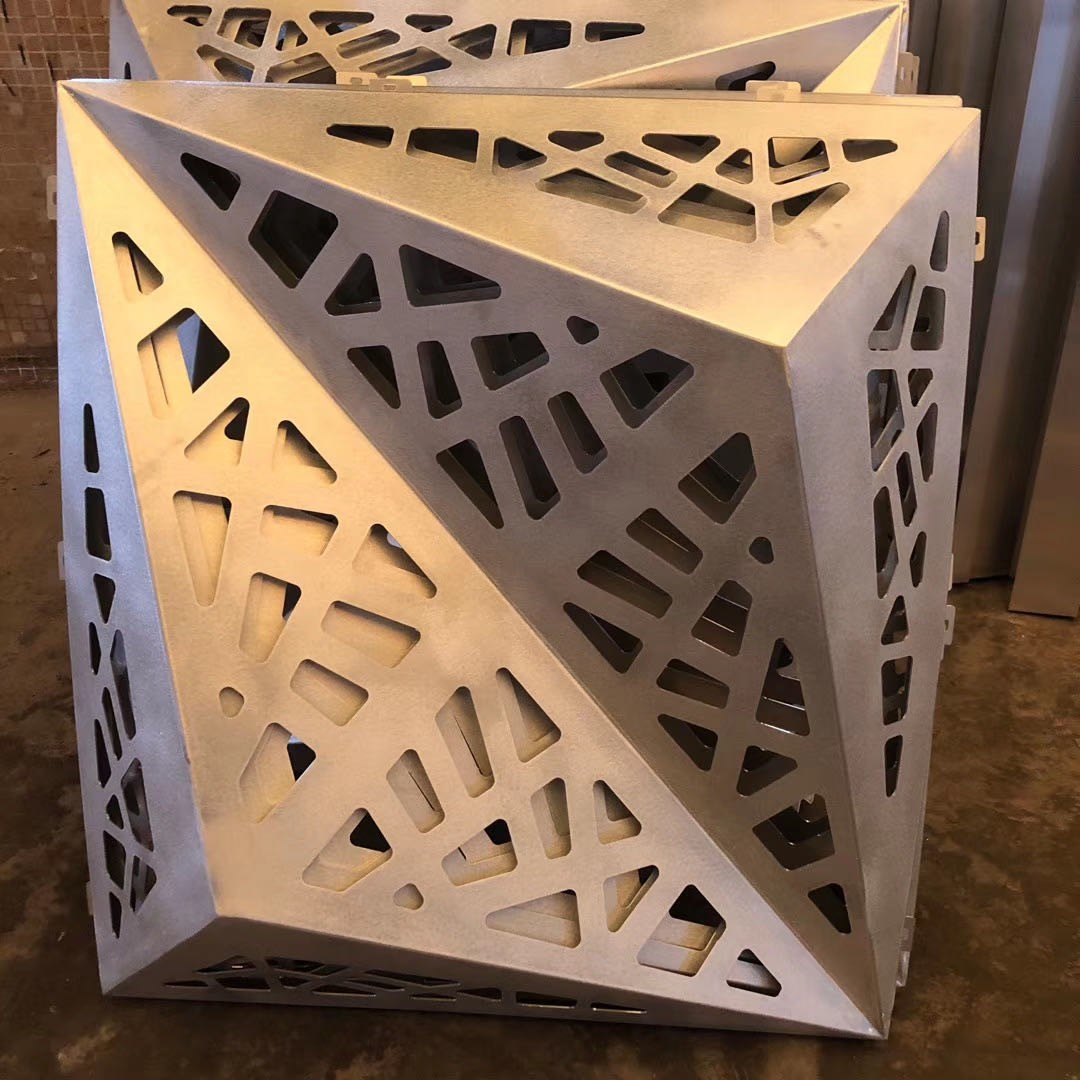

Aluminum veneer has rich colors and textures. Aluminum veneer can be produced in various colors and textures through spraying, rolling, and other methods, giving it a stronger artistic and decorative effect. These colors and textures can be customized according to the designer's design needs to meet different architectural decoration requirements.

Aluminum veneer has good plasticity and processability. Aluminum veneer can be customized in various shapes and sizes according to design requirements to meet different building decoration needs. It can also be carved and cut with higher precision and surface smoothness through the application of advanced technologies such as CNC machining and laser engraving.

Aluminum veneer can also be combined with other building materials. For example, aluminum veneer can be combined with other metal materials to create more complex decorative effects; It can also be combined with glass materials to create a more transparent decorative effect.

Aluminum veneer is widely used in the field of construction. In addition to being used as a building decoration material, it can also be applied in industries, transportation, and other fields. For example, in the industrial field, aluminum veneer can be used as a material for machine casings, pipelines, and other components; In the field of transportation, aluminum veneer can be used as a material for components such as car bodies and aircraft bodies.

Aluminum veneer, as a unique architectural carving material, has many advantages and applications. Through reasonable design and application, we can fully leverage its advantages and improve the overall quality and aesthetics of buildings. Although aluminum veneer has a wide range of application prospects in modern architectural decoration, there are also some issues that need to be addressed. For example, how to ensure the quality and accuracy of punching, how to handle the relationship between punching and color, etc. These issues require us to constantly explore and research in practical applications.

Customer service QQ

Customer service QQ